This is a Veteran Owned site

|

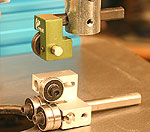

The Carter Stabilizer (top) replaces the upper guide head for using narrow blades, making installation a snap. Click image to enlarge |

Carter Stabilizers

Big Control over Little Blades

Text & Photos by Tom Hintz

Band saws are capable of cutting ultra tight curves when equipped with narrow blades. The problem has been controlling these little blades. The narrow blade body behind the teeth does not provide sufficient contact surface for block or roller style guides to be effective.

The Carter Stabilizer is designed to control narrow blades in a way block or roller style guides cannot. A groove in the singe roller of the Carter Stabilizer essentially traps the rear edge of the blade, helping it resist twisting and wandering.

Installation

|

Centering the groove on the back of the blade and putting 1/8" of preload on the blade is all it takes to align the Stabilizer. Click image to enlarge |

The Carter Stabilizer replaces the upper guide assembly. Installation involves removing the blade, the upper guide assembly and retracting the lower guides away from the blade area. With the Carter Stabilizer in place of the upper guide head, install and tension the blade and then adjust the Carter Stabilizer so the groove aligns with the back of the blade. Slide the Carter Stabilizer forward to put 1/8" of preload on the blade and the installation is done.

In the Shop

Installing and setting up the Carter Stabilizer on my Delta X5, 14" bandsaw took considerably less time than I anticipated. This is in part due to there being only one bearing/wheel needing adjustment. I had to shift the Carter Stabilizer grooved bearing to one side slightly to align with the back edge of the blade. I then moved the Carter Stabilizer assembly forward enough to put a 1/8" preload on the blade as prescribed in the directions.

|

Spinning the wood around the blade produced a small, cleanly cut circle attached to my in and out path. Click image to enlarge |

The entire installation and adjustment procedure took less than 15 minutes. Keep in mind that my installation times are generally slightly longer because of stops for photos and taking notes.

Using the 3/16"-wide TimberWolf blade was remarkably easy. Despite my long-time ineptness while scrolling with a bandsaw, the blade remained stable and tracked perfectly.

Spinning the wood around the blade produced a 3/8"-diameter cylinder with surprisingly smooth sides. That is due in part to the quality of the blade but has a lot to do with the blade not twisting and trying to spring back during the cut.

The Carter Stabilizer was doing its job well.

Freehanding a heart shape went so smooth I decided to freehand another from inside of that one. While I would like to think that I am suddenly becoming talented on the bandsaw, I suspect the majority of the credit for my newfound capability goes to the Carter Stabilizer.

Conclusions

If you cut tight curves or do scroll work on the bandsaw, the Carter Stabilizer will improve cut quality and prevent the premature wear to the blade that twisting can induce. In addition to the positive effects the Carter Stabilizer has on a bandsaw, the $69.95 price (12-11-2005) means you can enjoy this bit of American-made technology without torturing the budget.

Do you have a comment on this review? – Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.