This is a Veteran Owned site

|

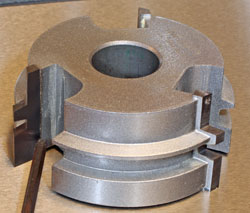

Everything about the Infinity Tools shaper cutters is first rate, as you would expect if you have used their router bits. Click image to enlarge |

Infinity Tools Shaper Cutters

The same Infinity quality, just bigger

Text, photos and video by Tom Hintz

Posted - 3-21-2009

Like many of you, I am a long-time fan of Infinity Tool router bits. They have performed very well, handling everything I have thrown at them with ease. Consequently, you would be hard pressed to find another brand in my router bit drawers. With that experience, I knew where to go for cutters when I got my shaper. Once again, Infinity Tools did not disappoint.

Design, Materials and Workmanship

Infinity has always been about solid design and manufacturing, properties that made their cutters more effective rather than just good looking to potential buyers. Infinity uses high-end materials that help their cutters maintain accuracy and durability. Infinity also applies high-tech, non-stick coatings that help the cutter bodies resist contaminate buildup that could generate balance issues, induce excess heat and compromise cut performance.

|

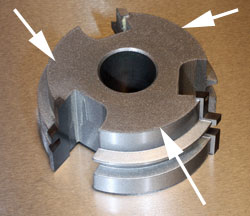

|

All of the Infinity shaper bodies (top) are CNC machined and given a special non-stick coating to help them perform better. Even their rub collars and bushings (bottom) are precisely machined to keep the cutter turning true and smooth. Click images to enlarge |

The cutter bodies are CNC (computer numerically controlled) machined to exacting tolerances throughout the manufacturing process. Though more expensive than other manufacturing techniques, CNC machining insures ultra precise dimensions, symmetry and balance. Critical bore sizing is extremely accurate to eliminate even tiny alignment or wobbles that would compromise cut quality.

The carbide used to make Infinity knives is very fine-grained, a property that enables them to take an extremely sharp edge and to retain that sharpness for a remarkably long time. The flat surfaces of the knives are polished to a mirror finish that also helps reject buildup. The carbide knives are attached to the Shape-Up™ Infinity cutter bodies using sophisticated brazing techniques that keep them solidly in place.

Infinity offers two lines of shaper cutters. Their Shape-Up™ cutters have fixed knives, steel bodies and 3/4"-diameter bores. Their Insert Pro™ versions feature replaceable knives that give you more options, high grade aluminum bodies and 1-1/4"-diameter bores.

Both the Shape-Up™ and Insert Pro™ cutter styles from Infinity feature carefully designed shear angles whenever possible. This "tilting" of the cutting edges helps produce more of a slicing action rather than chopping. That slicing motion produces a much smoother surface and tends to keep the edge sharper longer because there is considerably less impact.

Infinity also offers a full range of bushings and rub collars that precisely adapt cutters to nearly all popular shapers and spindle diameters. All of these accessories are remarkably precise and fit the cutters and spindles closely to prevent misalignments and wobble.

Shape-Up Cutters

|

The three cutters and anti-kickback body design makes the Shape-Up™ cutters very effective and safe. Click image to enlarge |

Infinity's Shape-Up™ line has the largest number of profiles. Despite their lower overall price, the Shape-Up™ cutters are first rate throughout from the CNC machined steel bodies to the micrograin carbide knives.

The Shape-Up™ cutters also feature the safe and effective three wing design that dramatically increase the cuts per inch without having to increase rpm to dangerous levels. The extended body between the three cutters also provides good anti-kickback properties.

Infinity offers their Shape-Up™ cutters in a wide range of profiles that will handle nearly every job in your shop. Several of the models actually have two (or more) profiles on the same cutter. Dual profiles saves you time and money. And, Infinity has a habit of expanding their lines regularly so if you don't find the exact profile you want, stay tuned.

Insert Pro Cutters

Infinity introduced the Insert Pro™ feature in their router bits a few years ago and has brought that technology to the Insert Pro™ shaper cutters. These replaceable cutters offer extended versatility and can lower costs in the shop considerably.

|

|

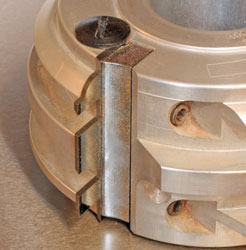

The easy-to-replace knives (top) make the Infinity Insert Pro™ cutters effective and save money. They also have taller models(bottom) that use the wedge bar for securing and supporting the replaceable knives. Click images to enlarge |

Each Insert Pro™ cutter has a fully CNC machined, high-quality aluminum body covered with the familiar Infinity silver non-stick coating. However, the knives are attached with screws instead of brazing. This allows using one cutter body with multiple sets of knife profiles. It also means that dull or damaged knives can be replaced without having to replace a perfectly good cutter body.

Infinity says that because the Insert Pro™ knives are secured with screws rather than brazing, they can use a much harder carbide compound that would be compromised by the heat of brazing. That increased hardness means a sharper edge that resists wear better than carbide knives formulated to be compatible with brazing.

Most of the Insert Pro™ knives are secured with a pair of high-end screws. The knives are precisely located with one or two special flat head screws that insure proper alignment and keep all of the knives working equally for the best possible finish on the wood. Infinity includes a special hand driver that fits the knife retaining screws. This mounting system makes changing out the carbide knives fast, easy and very accurate.

Some of the taller Insert Pro™ cutters use a wedge bar to both secure and support the carbide knives. The wedge bar is a tried and true system to keeps the knife locked in place and provides tremendous support.

In the Shop

One of the secrets to the superior performance of the Infinity shaper cutters is their precise fit on the arbor. That means that you might have to actually pay attention when installing or removing these cutters but once installed, there is no discernable play between the cutter and spindle. That means that they run very true and vibration-free. Even the bushings and rub collars Infinity sells are very close fitting to maximize their performance as well.

Video Tour |

Though I used some of these cutters extensively during this and other recent reviews, the cutting edges have stayed sharp. I have not been able to notice any decrease in their performance. The surfaces they cut are just as smooth and wave-free today as they were on the first pass.

I purposely removed and replaced knives on the Insert Pro™ cutters several times to see how easy they were to change and if they would return to proper alignment. That turned out to be wasted effort because they return to their exact position every time. You do have to make sure that the knife and its seat on the cutter body are clean before assembly but after that the process is remarkably automatic.

I ran a bunch of pitch-heavy pine using Shape-Up™ and Insert Pro™ cutters to see how well the coatings worked. Cleaning the bits up afterward turned out to be very easy and usually required just a soft brush or rag. I found that a soft brass-bristled brush does a good job of getting out the debris around the knives without endangering your fingers.

Conclusions

If you use a shaper, you owe it to yourself to give the Infinity Shape-Up™ and Insert Pro™ cutters a hard look. The prices vary from cutter to cutter but all are very reasonable for tooling of this quality. Knives for the Insert Pro™ cutters run around $30 each, allowing you to build multiple profile capability at a fraction of the cost of buying the entire cutters.

If you need shaper cutters, take a look at the link below to see the current Infinity Tools lineup or to order one of their extensive full color catalogs. Infinity Tools shaper cutters are only available directly from Infinity.

Visit the Infinity Tools website - Click Here

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.