This is a Veteran Owned site

|

The Irwin blades are well made and nicely designed for the massive woodworking community. Click image to enlarge |

Irwin “Marples” Saw Blades

Made in Italy, the land of great blades

Text, photos and video by Tom Hintz

posted – 6-10-2012

Italy has long been recognized by woodworkers as the land from which great saw blades come. When IRWIN wanted to get into manufacturing saw blades they wisely decided to locate that manufacturing facility in Udine, Italy. Now with a state-of-the-art facility staffed with blade-savvy employees and a stringent list of design standards the Irwin “Marples” Saw Blades are coming to stores near you.

The Basics

The Irwin “Marples” Saw Blades begin with a laser-cut body that is properly heat treated and tensioned to insure rigid performance. The laser cutters are also used to carve out expansion and anti vibration slots that help keep these blades running true as normal operating temperatures rise. To further help limit distortion the Irwin “Marples” Saw Blades are given a non-stick coating that in addition to dramatically reducing friction also has heat-rejecting properties. This coating also reduces gumming and other buildup of contaminates that are common when cutting wood which means the blade cuts better longer and you have to clean it less.

|

|

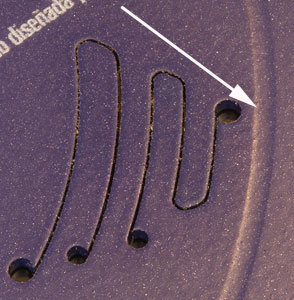

To prevent distortion in these narrow kerf blades Irwin builds in quality heat treating and anti vibration slots (left) along with a precise tensioning ring (left, arrow). To make these blades safer Irwin added these subtle but very effective anti kickback "humps" (right, arrow) that keep the wood from falling into the gaps at the gullets. Click images to enlarge |

|

Because of how the body is made Irwin “Marples” Saw Blades come in narrow kerf only because extra body thickness is not required to prevent distortion. That makes these blades useful to just about everyone from the folks with Benchtop saws to low horsepower full sized machines. The narrow kerf Irwin “Marples” Saw Blades also perform well in miter applications.

The Irwin “Marples” Saw Blades will be available in a wide range of designs for many applications and materials. Blades in 10” diameter are available with 24, 40, 50, 60, 80 and 84-tooth counts. In 12” diameter you can find 40, 60, 80, 96 and 100-tooth counts. Most blades will feature the ATB+R tooth pattern. That means alternating bevels for clean, chip-free edges and a raker for flat-bottomed grooving type cuts. The Irwin “Marples” Saw Blade will also include an 8” Stacked Dado set!

Big ‘r Teeth

OK, they aren’t visibly bigger but the high-end carbide teeth on the Irwin “Marples” Saw Blades are intentionally oversized to allow for multiple normal sharpening’s. That extends the life span of these blades considerably and that dramatically reduces your overall cost of owning them.

All of that carbide won’t help much unless it stays on the blade. The brazing on these blades looks first rate and should rule out any problems other than accidentally trying to cut something very wrong with them.

In the Shop

|

|

The alternating bevel tooth design (left) goes a long way towards making the clean, accurate cuts in a variety of wood as shown in the above right photo. Click images to enlarge |

|

I put the 50-tooth Irwin “Marples” Saw Blade on my SawStop Professional Cabinet Saw to see how it performed. For those using the SawStop machines, the stick-free coating on this blade will not fake out the brake system because there is no coating on the teeth themselves. Contact at the bore of the blade and the teeth keep the sensing circuitry operating.

This Irwin “Marples” Saw Blade has 50-teeth arranged in an ATB+R (alternating tooth bevel plus raker) pattern and features a 15-degree hook which should make it a very middle-of-the-road performer in terms of crosscut vs. rip. That proved to be true throughout the evaluation as through many cuts from cross to miter and rip the Irwin “Marples” Saw Blade performed very well. I also did all of these cuts in poplar, red oak and Lauan plywood that frays at the thought of being cut. The Irwin “Marples” Saw Blade did as well as any I have tried in all of the situations and woods, leaving behind clean, straight cuts.

Despite the narrow kerf thickness of the Irwin “Marples” Saw Blade I could find no evidence that it was trying to waver or deflect in even steep miter cuts at the table saw. The performance of the teeth is also first rate and produces a nice feed rate that is easy to maintain. This will be especially important on lower power saws that will let you cut more effectively yet come away with a straight, true cut.

Conclusions

The Irwin “Marples” Saw Blades are both well designed and well made, both of which are not surprising from a powerhouse tool manufacturer like IRWIN. The range of blade styles means there is a blade for just about any kind of woodworker out there. The quality and durability of these blades mean that with normal care you can count on the Irwin “Marples” Saw Blades performing for a very long time.

Video Tour |

IRWIN Marples Woodworking Series saw blades range in price from $28.00 to $100.00 (6-9-2012) and can be purchased at Lowe’s or your favorite local hardware store, lumberyard or online retailer. Being able to find the Irwin “Marples” Saw Blades in so many local outlets is just icing on this cake.

Visit the IRWIN web site – Click Here

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.