This is a Veteran Owned site

![]()

|

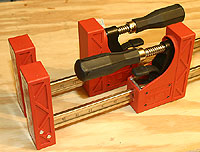

JET's Parallel Jaw Clamps feature high-end quality with innovative design features that make them very easy to use. Click image to enlarge |

JET Parallel Jaw Clamps

Traditional style - innovative and user-friendly updates

Text & Photos by Tom Hintz

Posted – 12-5-2006

Parallel jaw clamps have been around along time and widely regarded as the best clamp style for just as long. The JET Parallel Jaw Clamps have several new built-in features that make this already effective clamp design more versatile, easier to use and more accurate. Remarkable in today’s tool marketplace is that JET managed to do all this without sacrificing quality or pricing the hobbyist out of the picture.

Initial Impressions

From the pure heft to the precise fit and finish, it is obvious that the JET Parallel Jaw Clamps are meant to be buy-them-once tools. Everywhere you look, the components appear oversized for the job. The controls are comfortable, nicely arranged and easy to use. Even the Cross Doc™ Framing Blocks and Bench Dogs included in the JET 12-piece Framing Clamp Set reviewed here are equally well made and designed with the average workshop in mind.

The JET 12-piece Framing Clamp Set featured in this review includes two 40” and two 24” clamps, four Bench Dogs and four Cross Doc™ Framing Blocks. Incidentally, JET rates their clamp lengths by the actual between-jaw capacity, not the overall length.

The Basic Clamp

|

|

(left) The jaws are large enough to allow clamping 3/4"-thick material to the side of the bar, a feature that will come in handy more often than you might think. (right) The Acme thread that applies pressure is smooth and resists binding very well. Click images to enlarge |

|

The JET Parallel Jaw Clamps are built around a traditional design that has been tweaked by JET’s forward-thinking engineers to make them easier to use, especially in the one-person home woodworking shop.

The jaws are 1 9/16”-wide and 4 1/8”-tall (above the bar) to provide ample clamping surface that makes assembling box-type projects much easier and more accurate. The JET Parallel Jaw Clamp jaws are leaned towards each other slightly so that under pressure, they go parallel. This insures that the work pieces do not slip up and remain square to each other under pressures up to 1,000 lbs! Applying the precise amount of pressure necessary for the task at hand is made easier by the smooth-operating, non-binding Acme-style thread on the operating shaft.

The width of the jaws means there is ¾” of surface width (6”-tall) to the sides of the bar that makes clamping thin pieces easy and secure.

|

|

(left) For even more versatility, the JET Clamp head can be reversed to apply outward pressure. (right) To get the bar back through the close-fitting locking plates that make these clamps so secure, I found standing the clamp on end so you can see into the head to guide the bar through the plates easily. Click images to enlarge |

|

The jaw structure is covered with a special composite resin that is very durable and glue resistant. Glue may still dry onto the jaw surface but pops off easily. The composite resin covering is also non-marring to protect your projects.

Even the twist handle that controls clamping pressure did not escape the JET engineering department. Dubbed the SUMOGRIP™ Handle, the grip is 4 ½”-long with a maximum diameter of about 1 ½”. The handle size alone makes applying clamp pressure easy but JET added rubber grip inserts that virtually eliminate slipping.

The multi-plate mechanism that locks the JET Parallel Jaw Clamp head needs little explaining other than it is automatic, positive and simply does not slip. Period.

Woodworkers occasionally need to spread parts to bring them into alignment or to push pieces apart to make repairs. To accommodate these needs, the head of the JET Parallel Jaw Clamps can be removed from the bar and reversed.

Slide-Glide Trigger

|

The Slide-Glide Trigger makes these clamps very easy to use, especially with one hand while the other is holding the pieces to be clamped! Click image to enlarge |

One of the new features that instantly caught my attention is the Slide-glide (patent pending) Trigger. Lift the lever, located just below the twist handle to release the clamping head so it can be positioned where it is needed. Release the Slide-Glide Trigger and the head stays put, even when the JET Parallel Jaw Clamp is held up on end. No more trying to hold the handle at the right angle to adjust the head position or having the moveable head slam shut when the clamp is picked up.

The Slide-Glide Trigger alone gave me that warm fuzzy feeling. The first time I used the JET Parallel Jaw Clamps, being able to position the clamping head against the pieces without everything falling apart made me a big fan of this feature.

Graduated Bar

Even the bar on which the JET Parallel Jaw Clamps are based did not escape scrutiny. At 1 1/8”-tall and 3/8”-wide (max) the hourglass-shaped bar makes an extremely rigid backbone. The bar is also fully plated to resist corrosion and make cleaning up glue drips easier.

|

Adding a numbered scale to the bar was a very good idea that makes setting the JET Clamps up for the job much easier. Click image to enlarge |

The Precision-Rule™ Measurement System (patent pending) is an inch scale printed in the cove on either side of the bar that precisely indicates the distance between the fixed and moveable jaws. This may seem like a simple addition but makes setting the JET Parallel Jaw Clamps up much easier. If you have ever glued and held a project together only to discover the clamps are not set quite wide enough – and you are out of hands to make the correction – the JET Parallel Jaw Clamps graduated bar will be much appreciated.

The end stop on the rail can be repositioned easily to serve as a guide for pre-positioning the clamping head or to help stabilize the clamp on the work surface. The height of the end stop keeps the clamp bar level while suspending the moveable jaw slightly so it does not drag on the surface when adjusted. The bottom of the end stop also has a threaded metal insert that accepts the Bench Dogs described later.

Bench Dogs

|

|

(left) The 2-piece JET Bench Dogs are very useful, even when you don't have a bench! (right) The clamps themselves as well as the Cross Doc™ Framing Blocks are prepared for the Bench Dogs. Making your own, specialized clamping board is a no-brainer that will save time and space. Click images to enlarge |

|

The specially designed, two-piece Bench Dogs make setting up repetitive clamping jobs easy and fast. With a diameter just under ¾”, the JET Bench Dogs will fit most existing holes in commercial workbenches or you can drill the pattern needed for your job.

Each 2”-long JET Bench Dog is made up of two pieces, both with a threaded stud that allows them to be installed in the JET Parallel Jaw Clamps or the Cross Doc™ Framing Blocks. The 11/16”-long top portion is designed for use in ¾”-thick plywood or MDF. That allows making easy to store clamping jigs for common jobs easy.

If you build a certain sized door or frame frequently, the JET Bench Dogs can be screwed into the bottom of the Cross Doc™ Framing Blocks allows using one sheet of MDF with multiple hole patterns for several clamping jobs. Set the Bench Dog/Framing Block assemblies in the holes for that job, put the clamps in the blocks and you are ready to go.

Cross Doc™ Framing Blocks

|

|

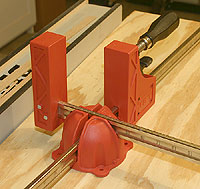

(left) The Cross Doc™ Framing Blocks make setting the JET clamps up square and steady easy. (right) The Cross Doc™ Framing Blocks can be installed using screws through the corner holes or with the Bench Dogs. Click images to enlarge |

|

Designed to hold two pairs of clamps 90-degrees to each other, the Cross Doc™ Framing Blocks make a once clumsy job simple. Each block has two grooves sized to fit the JET Parallel Jaw Clamp bars but at two different heights. That makes it possible to apply clamping pressure to the ends and sides of the project at the same time. They also allow setting the clamps up perfectly square before gluing the assembly up. Nothing is more aggravating than having a slightly crooked clamp push an assembly out of square.

Each Cross Doc™ Framing Block has holes for screws at the corners for attaching them to a board. They also have a threaded metal insert in the bottom for use with the JET Bench Dogs.

It doesn’t get any easier.

In the Shop

|

The JET Parallel Jaw Clamps have lots of range, apply even pressure and are exceptionally easy to use. Add the quality construction and they become the only clamps you need. Click image to enlarge |

Its hard to describe how much easier a good parallel jaw clamp makes many glue up jobs as compared to the cheaper pipe clamp designs. The innovative features and high-end manufacturing of the JET Parallel Jaw Clamps go well beyond the norm. The screw handle works very easily and requires surprisingly little effort, a trait that makes applying just the right amount of clamping pressure to a joint without accidentally squeezing out the glue a much easier task. That control makes producing a project that is truly square easier as well.

The Slide-Glide Trigger is itself worth the price. Being able to adjust the moveable jaw to the project size with one hand and without having the project being shaken apart in the process will be new territory for most of us. Just why this has not been a standard feature of parallel clamps all along is a mystery to me, but I will be forever thankful that JET came up with it!

The Cross Doc™ Framing Blocks and Bench Dogs are far more helpful than I initially thought. The Cross Doc™ Framing Blocks make setting up the JET Parallel Jaw Clamps to build a frame is very easy because the clamps don’t fall over and they are held square. If you take just a couple minutes to lay out the Cross Doc™ Framing Blocks to be sure they and the clamps they hold are square, building a crooked door or frame is actually difficult.

Video Tour! |

The Bench Dogs may sound “old school” but the innovative two-piece design fits the modern woodworking shop very well. Many higher end commercially produced benches have holes in them that will fit the JET Bench Dogs. The Bench Dogs have an outside diameter of 23/32”, allowing them to drop into hand-drilled ¾”-diameter holes easily. If you have to make several similarly sized doors or frames, a simple but accurate jig can be made from a sheet of ¾”-thick MDF or plywood. Being able to combine the Cross Doc™ Framing Blocks and Bench Dogs is an even better idea that further extends the possibilities.

I made a simple, easy to store clamping board from a 2-foot by 4-foot piece of ¾”-thick Lauan plywood. After drawing a simple, square grid representing the major clamping schemes I could think of, I drilled ¾”-diameter through holes with a hand-held drill at the intersections. Adding task-specific patterns later is easy because the clamping range of each JET Parallel Jaw Clamps allows one pattern to handle a wide range of project sizes.

The reversible clamping head may not be needed frequently but can save the day when the situation arises. The precise fit of the mechanism plates that lock the sliding head well also make reversing the head a little difficult. I found that standing the clamp on end, fixed jaw down lets you look down through the clamping head to guide the bar as you feed it through the locking mechanism. Hold a little pressure on the release trigger and the process is actually pretty easy.

The JET Parallel Jaw Clamps are very easy to use. All of the features described earlier make clamping wood square and with the right amount of pressure very easy. Quite simply, the JET Parallel Jaw Clamps work better than any similar clamps I have tried.

Conclusions

Clamps are some of the most important tools in woodworking and can have a major impact on your projects. Spending the extra dollars to get good ones the first time around will undoubtedly save money in the not so distant future.

At this writing (12-2-2006) the 12-Piece JET Parallel Jaw Framing Clamp Kit featured in this review is in short supply but that should change soon. Individual JET Parallel Jaw Clamps (sometimes packaged in pairs) in lengths from 12” to 98” lengths with street prices ranging from $35.35 to $66.50 each. (12-2-2006)

That combination of quality, innovative design and price make the JET Parallel Jaw Clamps a very good investment made even better by the lifetime warrantee that covers them.

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.