This is a Veteran Owned site

![]()

|

|

This simple but effective accessory will save you time and money - providing you use it! |

JET Diamond Truing Tool

Keeping it round

Text & photos by Tom Hintz

Posted – 10-7-2006

No matter what you do, sooner or later the grinding wheel will begin going out of round. The problem is that once this deformation starts the process gains momentum. As the tool being sharpened dips into the low spot on the wheel, the leading edge scrapes or digs away a little more material. As that irregularity deepens, the tool digs a little faster. The only way to stop this process is to true the wheel.

The hard part is convincing users that truing the wheel sooner rather than later actually prolongs the life of the grinding wheel. Truing the wheel when the deformation is small and very little material must be removed to fix it. Procrastinate and before long the amount of material that must be removed multiplies. The JET DT-1 Diamond Truing Tool does a good job of refurbishing the wheel surface. Caught early and using a simple setup technique, the JET Diamond Truing Tool can be set to take the lightest cut necessary to true the grinding wheel up.

Finding the Dip

|

|

(top) Use the support arm to locate and then mark the low spot on the wheel. (bottom) A folded piece of paper makes a quick, accurate setup tool that produces a cut depth of about 0.008". Click image to enlarge |

Put the support arm in the horizontal mounts and adjust it to within 1/8” of the grinding stone surface. Slowly turn the wheel by hand while watching the gap between the wheel and support arm. When the gap is the widest, draw a pencil line across the face of the grinding wheel using the support arm as a guide. It is important to watch both edges of the grinding wheel as well as the face as wearing it at an angle is just as big of a problem as an out of round condition.

Move the support arm to the top mounts and loosely install the JET Diamond Truing Tool, the U-shaped stop arm bracketing the wheel. Adjust the height of the support arm so that the cutting tip of the JET Diamond Truing Tool is flat on the grinding wheel.

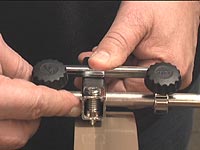

Turn the grinding wheel to bring the line made earlier beneath the cutting tip of the JET Diamond Truing Tool. With the cutting tip held lightly on the grinding stone, fold a piece of common paper once and place that double layer of paper between the top of the cutting tool bar and the underside of the u-shaped bracket. Adjust the bracket so that it lightly holds the paper against the JET Diamond Truing Tool bar and tighten both of the locking knobs. With the paper removed, the tip will cut into the grinding stone surface approximately 0.008”.

Barring deep gouges, this 0.008” cut depth is usually sufficient to true the grinding stone face with minimal loss of wheel diameter. If more material must be removed, making a second cut rather than increasing the cutting depth of a single pass produces a better surface while reducing the chances of chipping at the edges of the stone face.

Making the Cut

|

|

(top) A light, sideways pressure on the cutter lets it make a clean, complete cut in one pass that leaves little to be cleaned up. (bottom) If you took your time, a little work with the stone grader's coarse side finishes the surface. Click images to enlarge |

Before making the cut, saturate the wheel with fresh water and top off the tank to the indicator line. Set the speed control to 90 rpm.

Move the JET Diamond Truing Tool off the side of the wheel (whichever side is most comfortable) and start the JET Wet Sharpener. While holding the JET Diamond Truing Tool bar against the bottom of the bracket apply light pressure to the side of the cutting bar next to the cutting tip. The idea is to push just hard enough to keep the cutting tip engaged with the stone without forcing it. With the right amount of side pressure the JET Diamond Truing Tool will slowly move across the face of the grinding wheel as it clears the material away, leaving a clean, flat surface. It will leave fine grooves but those clean up easily with the stone grader.

When the JET Diamond Truing Tool gets about ¼” from the other side, lighten the sideways pressure to let it cut more slowly. Letting the tool gently cut its way off the edge of the stone substantially reduces the chance of chipping that sharp corner. Continue holding the JET Diamond Truing Tool bar up and let it work its way completely off of the grinding stone. Check the surface to be sure you didn’t skip a spot and go back to clean it up if you did.

Video Tutor |

|

Click the bandwidth links below to see a short Windows Media video of the JET Diamond Truing Tool in use as described in this story. |

Remove the JET Diamond Truing Tool from the support arm. With the JET Wet Sharpener speed control still set at 90 rpm, use the coarse side of the stone grader to finish smoothing the shallow lines left by the JET Diamond Truing Tool from the surface.

Before going back to sharpening, the tank must be emptied and rinsed out to get rid of the grit and debris removed from the grinding wheel. Re-fill the tank with fresh water and the JET Wet Sharpener is ready to sharpen the next tool.

Taking the time to true the JET Wet Sharpener grinding wheel soon after it begins deforming will prolong its life. A truly round, flat wheel sharpens more accurately, faster and with less effort.

Resources

Pricing Link |

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.