This is a Veteran Owned site

|

|

Whether in the jointing mode (left) or set up for planing (right) the JET JJP-12 Jointer/Planer is a well built, capable machine. Click images to enlarge |

|

JET JJP-12 Jointer-Planer

A powerhouse in space-saver clothing

Text, photos and video by Tom Hintz

Posted - 10-24-2007

A large portion of today's woodworking populace work in small shop spaces. That deficiency in square footage, often coupled with an equally restrictive budget does nothing to reduce their machinery needs. The new JET JJP-12 Jointer-Planer combines the capabilities of the jointer and planer, two core woodworking machines, in one machine. The space and money savings are big, the capacity/capability loss is somewhere between negligible and non-existent.

Initial Impressions

If you are expecting a lightweight, light-duty compromise machine, the JET JJP-12 Jointer-Planer will surprise you. At 500-some pounds, lots of cast iron and a stout 220V motor, the JET JJP-12 Jointer-Planer is way more capable than compromise. I was pleasantly surprised at the construction and thoughtful design of the JET JJP-12 Jointer-Planer. You'd think I would be used to that from folks like JET.

Motor

|

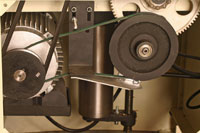

The 3 HP motor and drive belt system reside within the solid, all steel base cabinet. Click image to enlarge |

The JET JJP-12 Jointer-Planer sports a 3 HP, 220V motor that is plenty strong for even hyperactive weekend woodworkers. If you are slowing this motor, your feed rate and/or cut depth are way out of what sane people consider reasonable. Lighten up a tad and enjoy your life.

The motor power is delivered through a belt system that drives the cutterhead itself as well as the feed rollers. The feed rollers are engaged for planing operations and disengaged for jointing. A simple handle on the end of the JET JJP-12 Jointer-Planer handles the feed roller engagement/disengagement.

A magnetic switch is used on the JET JJP-12 Jointer-Planer to protect the motor and you. While significant fluctuations in electrical power are rare, they can be damaging to 220V motors well before you know they are happening so JET added this magnetic switch. The switch has a limiting feature that cuts out when the power varies significantly. A side benefit is that when the power goes out, the magnetic switch defaults to Off and will not allow the machine to restart whenever the power comes back on, eliminating one dangerous surprise we can live without. You must push the On button after the power is restored to restart the JET JJP-12 Jointer-Planer.

|

The single cutterhead assembly is familiar technology for JET and is used for both joining and planing. The feed rollers are engaged for planing only. |

3-Knife Cutterhead

The JET JJP-12 Jointer-Planer features a 2 3/4"-diameter cutterhead fitted with three high quality knives for both jointing and planing operations. The cutterhead spins at 5500 RPM for jointing and planing operations. The knives are secured with conventional wedge bars and use jacking screws beneath them for height adjustments. I have come to like this jacking screw arrangement because it makes being very precise with knife height adjustments.

Jointer

Some will infer that the 55"-long tables are too short for accurate jointing. That kind of forum-spawned logic has little to do with reality and nothing to do with the capabilities of the JET JJP-12 Jointer-Planer. If your jointing technique is reasonably correct, the JET JJP-12 Jointer-Planer is capable of making straight edges on material well over 110"-long. If your technique is lacking, jointer tables reaching into the neighbor's bathroom will not help.

|

The huge 12" jointer width capability exceeds the needs of most woodworkers, but it is nice to have around. Click image to enlarge |

Even the forum experts with the poorest attitude will have trouble convincing anyone that the JET JJP-12 Jointer-Planer lacks jointing width capacity. Because the jointing section uses the same cutterhead as the planer, you get a full 12" cut width on the jointing surface. For most woodworkers, 12" exceeds the widest boards they will ever work with by a few inches (at least) but it does allow jointing some glue-ups also.

Both the infeed and outfeed tables are height adjustable (1/8" cut depth max) using exterior handles. A nice feature is full coplanar adjustments for both tables and a section in the instruction manual that clearly explains how to do this, if needed.

The 6"-tall by 43"-long extruded aluminum fence is more than adequate for jointing. It has an angle adjustment (outward only) range of 45-degrees plus can be positioned to reveal any amount of the cutterhead.

Bridge Guard

|

The bridge style guard might take a little getting used to but works very well and is very safe. this style guard is popular just about everywhere but the US! |

The JET JJP-12 Jointer-Planer is equipped with a bridge-style guard system that is much like those used on European woodworking machines. Unlike the pork chop, swing-away guard styles American woodworkers are more accustomed to, the bridge guard remains over the cutterhead throughout the operation. Its height is adjusted to allow the wood to pass beneath it for face jointing and it can be adjusted to the side for edge jointing.

The bridge-style guard takes a little getting used to but actually works very well. In addition to keeping the cutterhead covered, the bridge guard forces you to stop pushing down on the wood directly over the cutterhead while face jointing. Most of us know we shouldn't be doing that anyway but JET and the bridge guard helps put this bit of common into practice.

Planer Mode

|

|

When in the planer mode, (left) the JJP-12 works like any stationary planer, including the controls (right) that are located on the infeed end of the cabinet. Click images to enlarge |

|

The JET JJP-12 Jointer-Planer features a 12"-cut width and a remarkable 8 3/4" maximum material thickness. The maximum recommended full-width cut depth is 1/8" and 5/32" maximum on narrower stock. That cut depth range is fairly standard for planers of all descriptions, as is the fact that lighter cuts always produce much better results.

The JET JJP-12 Jointer-Planer has a 5500 RPM cutterhead speed and a constant 20 FPM feed rate. While many planers have dual feed rates, this setup seems to be a good compromise between quick material removal and a clean, smooth surface. The feed roller system is only used for planing operations and is engaged/disengaged with an exterior handle.

The cutterhead assembly is fixed and includes a row of gravity-operated anti-kickback fingers for safety. A serrated metal infeed roller resists contamination and does a good job of maintaining a consistent material feed rate. After the cutterhead, a rubber-covered outfeed roller keeps the stock moving without marring the freshly planed surface.

Planing cut depth is adjusted by moving the 21 1/4" by 12" planer table up and down with a large handwheel (with spinner handle) on the infeed end (planer mode) of the JET JJP-12 Jointer-Planer. A scale on the handwheel hub indicates the amount of change as the handwheel is turned plus a full height scale with pointer shows overall cutter to table distance.

Changing Modes

|

|

Changing between the jointing and planing modes (left) is fast and very easy. The cast iron jointer tables and fence fell surprisingly light thanks to the "helper" springs in the hinges. Click images to enlarge |

|

An obvious point of concern with a multi-function machine is how labor intensive changing from one function to the other really is. JET did their homework on this point as changing the JET JJP-12 between Jointer and Planer modes is both simple and very fast.

A pair of locking handles, one on either side of the base cabinet releases the jointer table assembly. Lifting that assembly up is easier than expected because JET included a pair of strong compensating springs at the hinges that provide a noticeable assist. A gravity-operated lock falls into place when the jointer table assembly is fully up. All that remains is flipping the dust collection shroud from it jointing position to the planing mode. The planer table may have to be lowered to allow the dust shroud to clear during its rotation but compared to dragging out another machine, this concern falls deep into the nitpicking category. Engage the feed roller system and the JET JJP-12 Jointer-Planer is ready for planing. Reversing the process to return to the jointing mode is just as easy with no surprises.

In The Shop

Probably the hardest thing about using the JET JJP-12 Jointer-Planer is getting over the fact that it isn't more difficult to use just because it is a combination machine. Both the jointing and planing functions work just as they do on stand alone machines. In addition to the space and money saving convenience of having both functions in one machine you get the remarkable 12" jointing width capacity that would cost far more than the JET JJP-12 Jointer-Planer in a stand alone jointer.

See It Work |

The JET JJP-12 Jointer-Planer is made very well and the features well thought out. I was a little concerned about the fragility of a combination machine but the JET JJP-12 Jointer-Planer shows no signs of weakness or compromise. Between the sturdy construction and a powerful motor, the JET JJP-12 Jointer-Planer handled whatever I threw at it without a whimper.

The accuracy was a little surprising, particularly when jointing. With all of the on-line gnashing of teeth over jointer construction and always too short table lengths, the JET JJP-12 Jointer-Planer just cuts straight edges and leaves the uproar to the so-called forum experts.

While power never seemed to be an issue in either the jointing or planing modes, the JET JJP-12 Jointer-Planer is just like any stand alone machine I have tried; taking light cuts produces the best surface. Both modes work exactly as expected and require no additional steps or technique over what I would expect on single purpose machines. Making the change from one mode to the other is the only thing that is really different about the JET JJP-12 Jointer-Planer and that is largely because the process is very easy and fast.

The only feature I would like to see added to the JET JJP-12 Jointer-Planer would be a wheel system. At just over 500Lbs the JET JJP-12 Jointer-Planer is not easy to hustle around the shop. The combination of function and large capacity could very well mean the JET JJP-12 Jointer-Planer can be best used in various locations within the average shop. Putting one of JET's universal mobile bases under the JET JJP-12 Jointer-Planer is a good idea but a real set of wheels in the base cabinet would be a welcomed addition to this machine.

Conclusions

The JET JJP-12 Jointer-Planer is well built, thoughtfully designed and has cut quality and capacities that exceed the needs of most home woodworking shops. With an expected retail price in the $2000 range, the actual street price of the JET JJP-12 Jointer-Planer should meet or beat the cost of most 10" jointers of equal quality that have no planing capability. These are crucial factors for many woodworkers who have to deal with limited budgets and floor space. The JET JJP-12 Jointer-Planer saves both commodities very well.

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.