This is a Veteran Owned site

Porter-Cable 18 Ga. Brad Nailer (#BN125A)Reliable, versatile and economicalText & Photos by Tom Hintz When considering a brad nailer for the home woodshop, quality, reliability, range of fasteners and cost are all-important factors. The Porter Cable (PC) BN125A 18 Ga. brad nailer qualifies on all counts. Initial Impressions The BN125A comes in a nicely designed slim-line case that safely protects (and organizes) the brad nailer, tool oil, a ¼" male air connector, 1000 1 ¼"-long brads and instructions. Comfort and Control

The grip on the BN125A features a rubber-like insert that is molded into the body. The grip is both comfortable to the hand and reduces the already small amount of recoil. The insert's semi-tacky surface also gives the operator a solid feel of control even when holding the nailer at odd angles. Power to Spare

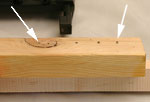

The BN125A uses an oiled air cylinder that is both slim and powerful. Adding a few drops of air tool oil before using takes seconds to do but insures a very long life and a crisp brad driving sequence. Nail-Driving MechanismThe mechanism that actually drives the brads is simplicity itself. A specially hardened driver blade harnesses the power of the air motor to drive the brads, with authority. The brads are driven straight and to the depth set by the adjustable dial control regardless of wood species.

Jam ClearingThe transition between the magazine and driver mechanism is seamless which virtually eliminates mechanically induced jams. However, wood is an inconsistent medium so PC added a tool-less jam clearing system. Disconnect the air supply, open the magazine and remove any remaining brads. Squeeze a lever to release the forward mounted door, swing it open and the brad path is totally exposed. Removal of the damaged brad is simple, assuming it doesn't fall out on its own. Depth ControlRemember when depth controls on air nailers came unlabeled? With most of the nailers I have owned in the past, that lack of labeling wasn't a concern because turning the wheel in either direction had little to no affect on nail depth. Those days are over.

The depth adjustment on the BN125A is clearly labeled with arrows and graphics. That is a good thing because turning that dial produces clear changes in how deeply the brad is driven. MagazineMade from hard-anodized aluminum in place of the plastic so common these days, the BN125A magazine holds 100 brads from 5/8" to 1 ¼"-long. Changing brad length requires no changes or adjustments of the magazine.

The left side opens fully by pushing a rear-mounted lever to allow easy loading or removal of the brads. A window near the front of the magazine cover either shows brads or when the supply gets low, an automatic red warning indicator. In the Shop The BN125A is a sweet piece of equipment to use. Regardless of the angle or type of wood, the brads were consistently sunk to the setting dialed in. Unlike other nailers I have used, the depth does not vary as the line pressure drops to where the compressor kicks in.

Despite its power and capabilities, the BN125A is very comfortable to use, light and well balanced, even with the air hose attached. Whether nailing up, down or sideways, putting brads exactly where you want them is easy. Conclusions The Porter Cable BN125A brad nailer is a top shelf tool for the home woodworker and professional alike. The quality of the materials and workmanship means the BN125A performs flawlessly and will maintain that level of operation for a very long time. Both are important attributes when the shop budget cannot be overlooked. Do you have a comment about this page? - Email Me!

|

||||||||||||||

Pricing Link |

||||||||||||||

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.