This is a Veteran Owned site

|

The updated line of Bessey Auto-Adjust Toggle Clamps kept all of the good features and made them a bit more compact to fit in more places in a real world shop! Click image to enlarge |

Bessey Auto-Adjust Toggle Clamps

Bessey has made the best toggle clamps better yet

Text, photos and video by Tom Hintz

Posted – 7-31-2013

Toggle clamps have always had utility in woodworking and metalworking shops. Unfortunately they have also been a pain to get set up to deal with the varying material thicknesses we often work with. Back in 2011 I reviewed the original line of Bessey Auto-Adjust Toggle Clamps because they turned this category of clamps on its collective ear. Now Bessey has stepped this type of clamp up again with a group of enhancements that substantially increase the range of applications as well as ease of use.

The Basics

All of the Bessey Auto-Adjust Toggle Clamps are made from high-quality steels using dependable manufacturing processes that insure consistent accuracy. There are lots of places for a manufacturer to cut financial corners in products such as these but the Bessey Auto-Adjust Toggle Clamps show no sign of that kind of fiscal foolishness. Bessey wants their products to last and they have maintained that selling point in the Bessey Auto-Adjust Toggle Clamps.

All Bessey Auto-Adjust Toggle Clamps feature easy-to-use composite handles that make applying pressure easy and comfortable. Closing a clamp once is one thing, having to do it over and over again such as when using the Bessey Auto-Adjust Toggle Clamps in a jig or fixture makes this handle design way more than eye candy.

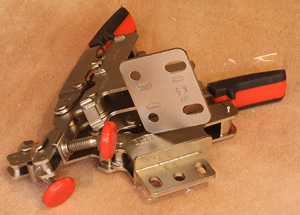

All of the Bessey Auto-Adjust Toggle Clamps, new and old had their mounting flanges updated. The mounting hole pattern accommodates layouts in metric or imperial formats. The positioning of these holes offers the user many options for mounting the Bessey Auto-Adjust Toggle Clamps. Many of the flanges are now brazed to the body, a more expensive manufacturing process but a more accurate and secure one. Bessey also improved the riveting process used for even more structural integrity.

|

|

Clamps with applied mounting plates (left) now have them brazed in place, a more costly but more secure procedure. All of the ends (right) feature swivel-mounted plates with removable no-mar covers. Arm reach adjustments are locked in place with a simple wrench. Click images to enlarge |

|

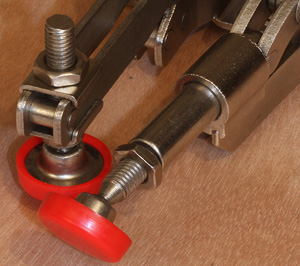

Another nice feature on all of the Bessey Auto-Adjust Toggle Clamps is the swivel tip that contacts the workpiece. This flat steel circle swivels easily to accommodate not-so-flat surfaces. When working with sensitive materials the Bessey Auto-Adjust Toggle Clamps come with a snap-on plastic no-mar cap that lets you apply necessary pressure without marking the material. All of the pressure arms are easily adjustable for length and are locked in place with a simple jam nut.

The five new Bessey Auto-Adjust Toggle Clamps models reviewed here feature a more compact overall size which makes them applicable in more situations. The smaller size also reduces the overall clamping pressure somewhat to a minimum of 25 to 250 lbs. That pressure range is still far more than is needed in the vast majority of situations we are likely to encounter. The reduced size means we can build smaller jigs and put effective clamps in smaller places which make the Bessey Auto-Adjust Toggle Clamps far more versatile.

Despite the smaller overall physical size the new Bessey Auto-Adjust Toggle Clamps retain the auto-adjust feature. This one feature makes the Bessey Auto-Adjust Toggle Clamps much easier to use. Because you do not have to re-set the clamp for each material thickness these clamps are much faster to use as well. Since the clamping pressure does not vary with material thickness you save even more time.

Adjusting Pressure

The clamping pressure on all of the Bessey Auto-Adjust Toggle Clamps is adjusted using a simple screw located at the joint. Just how that screw changes the clamping pressure is not obvious to me (lot of stuff isn’t, get over it) but it does work and it is very consistent. Set the clamping pressure and it is the same regardless of material thickness within the range of that clamp.

You don’t have to turn this screw much to make a substantial change in pressure. If the material is sensitive to pressure it pays to increase in small steps just to be sure. The good news is that the rate of change is constant across all of these clamps so once you get the feel for using the adjustment screw setups go much faster.

HH20 Bessey Auto-Adjust Toggle Clamps

|

|

The pressure adjusting screw (left) is deceptively simple to work. Many of the clamp styles are available in multiple sizes (right) so you can fit the clamp to the job more easily. Click images to enlarge |

|

This version of the Bessey Auto-Adjust Toggle Clamps is available with three mounting base choices with a total of 5 models from which to choose. This means that you can pick the one that best fits the job at hand rather than have to engineer a special mount.

The STC-HH versions of the Bessey Auto-Adjust Toggle Clamps have horizontal mounting bases. The STC-HH20 has a material capacity of up to 13/16”-thick, generates 25-250-lbs of clamping force and has a holding capacity of 450-lbs. The STC-HH50 holds materials up to 1-9/16”-thick, makes 25-550-lbs of clamping force and has a holding capacity of 700-lbs. The STC-HH70 has a maximum material capacity of 2-3/8”-thick, generates 25-550-lbs of clamping force and has a holding capacity of 700-lbs.

The STC-HV20 has a straight vertical mounting base, holds materials up to 13/16”, generates 25-250-lbs of clamping force and has a holding capacity of 450-lbs. The STC-HA20 has a 90-degree angle mounting base that gives you two mounting options that can extend the usefulness of this clamp in your shop. The STC-HA20 accepts materials up to 13/16”-thick, makes 25-250-lbs of clamping force and has a holding capacity of 450-lbs.

IHH15 Bessey Auto-Adjust Toggle Clamps

The in line versions of the Bessey Auto-Adjust Toggle Clamps are very popular for jig and fixture work because they deliver clamping pressure horizontally.

The STC-IHH in line clamps are available in two mounting styles. The STC-IHH has a flat, horizontal mounting base. The STC-IHA model has a 90-degree angled mounting base.

The STC-IHH15 has a maximum material thickness of 3/8”, generates 25-250-lbs of clamping force and a holding capacity of 450-lbs. The STC-IHH25 accepts material up to 5/8”-thick, generates 25- 550-lbs of clamping force and has a holding capacity of 700-lbs.

|

|

Both the in line style (left) and the vertical designs (right) are available with multiple mounting flange orientations to give you more options when building jigs or fixtures. Click images to enlarge |

|

The STC-IHA15 (90degree angled base) accepts material up to 3/8”-thick, generates 25-259-lbs of clamping force and has a holding capacity of 450-lbs.

In the Shop

While updating their Bessey Auto-Adjust Toggle Clamps nothing was done to complicate their use. This whole line of clamps remains remarkably simple to employ. That starts with the mounting bases which have a real-world hole pattern that makes it easy to secure the clamp with common fasteners. I think that people at Bessey actually use their products during design as they seem to find all the stupid interferences I find on way too many of other people’s products.

All of the setup adjustments use hardware that you can manipulate with common tools. All of the adjustments do what you expect them to and lock in place when you are satisfied. I have used the previous versions of the Bessey Auto-Adjust Toggle Clamps for years and have not had one lose adjustment or fail in any way. Throughout the evaluation the new Bessey Auto-Adjust Toggle Clamps perform the same way and have the same dependability.

I do like the more compact size of the Bessey Auto-Adjust Toggle Clamps as they allow using these clamps in more situations and that is important in my small shop. The physical size and capacities of the new Bessey Auto-Adjust Toggle Clamps seem to fit the home woodshop or metal shop very well. It is just natural that commercial shops will have a ton of the Bessey Auto-Adjust Toggle Clamps because they appreciate the durability and timesaving’s these tools bring.

Conclusions

Video Tour |

The Bessey Auto-Adjust Toggle Clamps are just the latest in a long line of well-designed and manufactured clamping products from this long-time favorite company. The Bessey Auto-Adjust Toggle Clamps are easy to use, easy to set up and now even easier to install in more applications. The quality of the materials and manufacturing processes used to create the Bessey Auto-Adjust Toggle Clamps mean they will last a very long time with simple common sense care on your part.

Just as important as usefulness and durability is price. Bessey has never been a “cheap at any cost” tool maker but they have always offered very good value for our tool dollars. The Bessey Auto-Adjust Toggle Clamps follow that tradition with the STC-HH20, STC-HV20 & STC-HA20 models having an expected street price of$21.50 (7-30-2013) each. The STC-IHH15 & STC-IHA15 models should sell for about $23.60 each. (7-30-2013)

If you need to add toggle clamps to your shop, considering the Bessey Auto-Adjust Toggle Clamps is a smart move to both make your life easier today and in the future. When you need this type of clamp there really is no substitution. When you want a good clamp, the Bessey Auto-Adjust Toggle Clamps look to be the best value.

See the original Bessey Auto-Adjust Toggle Clamps review – Click Here

Have a comment on this Tool Review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.