This is a Veteran Owned site

|

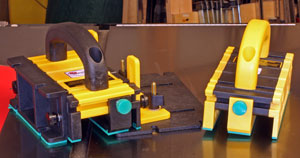

The GRR-Ripper on the left has all of the included pieces installed. The version to the right is in the basic configuration as you might use it for simple rips. Notice the two color variations? That really is the only difference between the two! I dunno why! Click image to enlarge |

GRR-Ripper® System

Adjustable stability and safety

Text, photos and video by Tom Hintz

Posted – 5-10-2012

The GRR-Ripper® System has been around for a decade or more and I have known about it for some time. My viewers have also been asking for this review but after my Kickback on Camera experience the interest in the GRR-Ripper® System among the NewWoodworker.com viewers and me went up a bunch.

The Basics

The GRR-Ripper® System is essentially a modified push block but those changes are important ones to say the least. The top-mounted handle remains but virtually everything below that has been redesigned to allow the GRR-Ripper® System to be easily configured for a range of common and not-so-common cuts without sacrificing stability which translates directly to safety.

In place of a single rubber covered bottom surface the GRR-Ripper® System has three primary “legs”, all with super grippy rubber soles that can be configured to precisely control both the main piece of wood and the cutoff piece throughout the cut! Just taking the cutoff piece out past the blade with the board it was cut from is a big safety improvement itself. Being able to control the cutoff during beveled rip cuts is even more of a safety factor introduced by the GRR-Ripper® System.

|

|

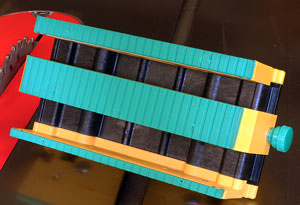

The three primary legs (left) show the different widths as well as the very grippy green rubber bottoms. This pile of pieces and hardware (right) is what comes in the package and leaves you with several hardware extras for making shop-built jigs and additions. Click images to enlarge |

|

Outboard legs and included attachments let you build-in super stability for virtually any stock and cut width. Simple shop-made wooden spacer blocks can be attached to outboard legs/plates that allow using the GRR-Ripper® System with essentially any material thickness we are likely to see in woodworking. Because all of the moveable components are secured with knob-handled screws adjustments and setups are usually quick and tool-free.

I know that the handle is only tentatively accepted by some people and I have to say that the Kickback on Camera footage opened my eyes on this point as well. It is clear that wrapping your fingers around a handle may well contribute to the forces of a kickback moving them in directions you don’t want them to go. However, any style handle that you grip to control a push block, handle or stick can exert similar influences on the motion of your hand during a kickback. I think that the safety of the GRR-Ripper® System device itself wins this argument every time. The GRR-Ripper® System is very effective at making you safer at the table saw, jointer and router table but that doesn’t mean you can go stupid or forget common sense.

The GRR-Ripper® System appears to be made from a glass-filled plastic or resin that has been precisely molded for strength and smooth interactions with other components. All of the pieces seem more than strong enough for wood shop use. The bottom surfaces of the vertical parts are covered with a rubber-like material that provides a solid grip on all types of wood, even with some sawdust on the surface. It is these grippy surfaces and the ability to space the center one as needed that makes the GRR-Ripper® System so safe and useful.

As versatile as the GRR-Ripper® System is right out of the box they include additional hardware for building shop-made fixtures for even more uses. The instruction manual has complete drawings and instructions for using the GRR-Ripper® System on a router table, jointer and more table saw operations. Once you get used to using the GRR-Ripper® System I am sure most woodworkers will come up with even more ways to adapt this unit to the kind of work they do.

In the Shop

|

|

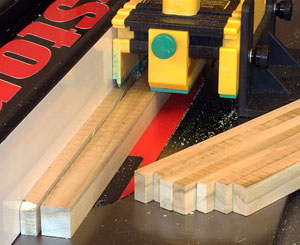

The GRR-Ripper gives you very good control over the work piece AND the cutoff (left) as shown here. Unfortunately I went bonehead and forgot to get the GRR-Ripper flush against the fence (right) and made a slice across the narrow leg. It still works just fine but I ordered a new one anyway as my punishment. Incidentally, the leg gave up to the blade just as it is supposed to. Click images to enlarge |

|

Getting accustomed to the stable versatility of the GRR-Ripper® System and its feel during use takes just a little bit of experience. I think the larger part of that time is invested in learning to trust the stability that can be so absolute that it almost feels foreign. But, that investment in time is very short because the GRR-Ripper® System repeats very well and you learn to recognize that stability for the safety and accuracy it provides.

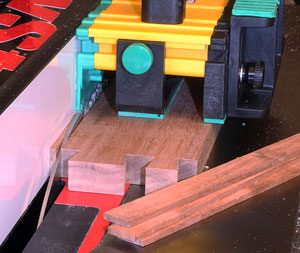

While one GRR-Ripper® System works fine for many board or part sizes many find using two GRR-Ripper® Systems even better. You can buy a piece designed to connect two GRR-Ripper® Systems together for longer work and to enhance dust protection. You can also buy a “zero clearance leg” that lets you cut thin strips down to 1/8”-thick easily, accurately and without having to reposition the fence after each cut!

The outer legs of the GRR-Ripper® System are ¼” and ½”-wide but the jig itself is omnidirectional so you can put whichever leg fits best over the cut or against the fence when not using the other attachments. An additional 1”-wide leg is included and can be added to either side of the GRR-Ripper® System. This leg has a flat smooth surface for use as a stability enhancer or a gripping surface that can be installed at the wood to provide additional control. The outside surface is a web with level surfaces that can slide along the fence. This leg can also be mounted at various heights for when it is used as a stabilizer.

The GRR-Ripper® System also comes with an L-shaped leg with a 2”-wide footprint that can be adjusted up and down approximately 2-1/2” to help stabilize the jig when working with moderate to thick stock. This piece can also be used at the router table. They also include a 5-1/4”-wide by 8”-long flat plate that can be used for stability, as a spacer to keep the jig spaced out for routing on a router table. It also has a hooked end that allows it to push stock across the blade at an angle while the GRR-Ripper® System itself remains square to the fence for consistency.

|

|

Another important thing that the standard GRR-Ripper does is control the cutoff (left) on bevel rips just as it does with square rips. Being able to push both the board and the cutoff out the back of the blade eliminates a possible shot back your way when the cutoff touches the blade. The Zero Clearance Leg (right) lets you cut thin strips down to 1/8"-thick and do it against the fence so yo can cut multiples without resetting anything other than the wood and GRR-Ripper! Click images to enlarge |

|

While preparing for this evaluation I went through as many scenarios as I could think of with the GRR-Ripper® System and found that it is easy enough to use that a couple test cuts with a new configuration is usually all it is going to take to be sure of the results. Once you understand the adjustments using the GRR-Ripper® System is very straightforward. Seeing how the included legs and pieces work will give you lots of ideas for shop-made pieces to adapt the GRR-Ripper® System to specific tasks you may encounter.

You will note in the video that I generously show what happens when I decide to record the first cuts I had made with the GRR-Ripper® System. I made a few cuts and the board started getting narrow so I installed the outboard leg on to stabilize it. Soon after that I forgot to put the GRR-Ripper® System flat against the fence, instead looking at my side of the wood as I reset the GRR-Ripper® System.

As I pushed it through the blade I accidentally show one of the very real safety features of the GRR-Ripper® System. The legs are made from a tough glass filled material that stands up to lots of things but not the blade - intentionally. When the blade encounters the leg I could feel some additional pressure but the GRR-Ripper® System remained stable and I easily finished the cut. Then I could see that I had made an angled path across the ¼”-wide leg. Even with part of that leg damaged the GRR-Ripper® System still felt stable so I carefully tried a couple more passes. The GRR-Ripper® System still seemed nice and stable without any feeling that it wanted to tip. The point was proven and I went up to my office to order a new leg because I am not going to continue using it like that. My bad, I gotta pay for the part.

You can also buy accessories for the GRR-Ripper® System that further extends its capabilities. The #GRP-11G 1/8” Side Leg works like a zero clearance tool and lets you cut slices down to 1/8”-thick without sacrificing stability or control of the cutoff piece. Also, the MJ Connector/Deflector (GRDC-020) can be mounted to your GRR-Ripper® System to work as a chip deflector or to join two GRR-Ripper®s to work in tandem on long material. These accessories either come with the needed installation hardware or use the pieces from the original GRR-Ripper® System.

Conclusions

Video Tour |

The GRR-Ripper® System is surprisingly easy to use but can have large effects on your woodworking in terms of accuracy and safety. Being able to control the cutoff pieces through the entire cut is a no brainer in terms of safety but also eliminates the annoying points so often missed by the blade when the wood stops before the cut is completed.

The design of the GRR-Ripper® System makes them extremely versatile which allows you to find legitimate uses for them in your shop. I truly believe that the GRR-Ripper® System is a tool that you need to have and use for a while before you fully understand the range of capabilities that it has.

The GRR-Ripper® System shown here has a street price of $69.99 each (5-10-2012) which includes all of the standard pieces shown in this review. Certainly not free but with a little common sense care there is no reason for the GRR-Ripper® System to wear out. If you make a mistake as I did, parts are available as well.

If you are not totally comfortable with your push blocks, you need to check out the GRR-Ripper® System. This is a well thought out and nicely made push device that has lots of utility in wood shops from the pros down to the hobbyist.

Visit the GRR-Ripper® System web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.