This is a Veteran Owned site

![]()

|

Visually, the Harbor Freight kit looks like a good value. If you didn't have to use it, that would be closer to true. Click image to enlarge |

Harbor Freight 18-Gauge Brad Nailer/Stapler

My first – and last – overpriced bargain tool

Text & photos by Tom Hintz

Posted 8-1-2006

After repeated offers from NewWoodworker.com viewers offering to send this nailer to me for review I decided to buy one and see for myself. While I appreciate those offers, the guidelines under which our Tool Reviews are conducted stipulate evaluating new products. Testing previously owned tools introduces variables that may not be fair to the tool nor its manufacturer.

The Kit

The Harbor Freight #40116, 18-gauge brad nailer/stapler kit comes with the gun itself, 480 – 1”-long ¼” crown staples, 480 – ½”-long ¼” crown staples, 500 each of 1” and 2”-long brads, a ¼” NPT air fitting, 3MM & 4MM hex wrenches, air gun oil and a blow-molded case.

It should be noted that the box is branded with the Central Pneumatic name and logo. However, a logo on the instruction sheet states this tool is distributed exclusively by Harbor Freight.

Initial Impressions

The first thing I noticed is that this is a heavy nailer for its size. Most of that weight is concentrated forward as the main portion of the tool, including the cylinder housing is cast from iron rather than magnesium or aluminum. The choice of material is certainly a cost-saving factor but should not impact the performance if the mechanism is designed and manufactured well. The decidedly weight forward condition could be tiring if you have a lot of fasteners to install.

|

Though designed to rotate 360-degrees, I had all I could do without a big wrench to get the exhaust outlet aimed a bit to one side. Click image to enlarge |

Overall, the outward appearance did not automatically arouse my “Oh-Oh” sensors. Inspecting the materials and workmanship does suggest reducing manufacturing costs was high on the design criteria list.

Exhaust

The reputedly direction-adjustable exhaust was nearly impossible to move by hand and stayed that way despite attempts to loosen it up by moving it back and forth. It was so hard to move that I began wondering if it was intended to be adjustable. The instructions and packaging make no mention of this feature but I did find it listed as a 360-degree exhaust in the product description on the Harbor Freight web site.

Eventually, I got the exhaust angled off to the side and there it will stay.

Jam Clearing

|

Better presentation of the jam-clearing photos would be helpful as you will need to know this procedure! Click image to enlarge |

While easy-access to the fastener path for jam clearing is standard fare on modern air nailers, that feature was not included on the Harbor Freight #40116. They do provide a hex wrench and nearly a full page of instructions – augmented with photos printed poorly enough to render some details indistinguishable – on how to take the gun apart to clear jams. While this system is more time consuming than the tool-free versions, chances are you will get enough practice to become proficient.

Depth Control

The wheel used to adjust fastener depth was also difficult to move initially. After working it back and forth through its range of adjustment, it became somewhat easier to turn. In doing that, I also noticed the amount of travel, stop-to-stop seemed rather small.

Safety Interlock

|

Neither the safety bar nor the gun tip have cushions, often resulting in small marks left in the wood. All things considered, this is the least of the problems. Click image to enlarge |

The Harbor Freight #40116 is a single sequential fire tool with no provision to convert it to bump fire. For the home shop, bump fire is not needed so this is a moot point.

Neither the safety actuator nor the nose of the gun has cushioned tips. The safety actuator is a simple bent wire with a rounded contact area that frequently left marks, particularly in softer woods such as pine and poplar.

In The Shop

While unpacking the Harbor Freight #40116 and looking it over, I noticed the internal threads at the air inlet looked rough. Though two full wraps of sealing tape were applied to the threads of the coupler, it leaked air. Adding two more wraps of Teflon thread sealing tape stopped the leak.

I ran the compressor up and set the line pressure to 70-psi, a bit low on the 60 to 100-psi operating range specified in the instruction manual. A strip of the 1”-long brads included in the kit were loaded in the magazine, a few drops of the oil added to the inlet and the air hose connected.

|

|

The most consistent thing about this gun is how inconsistent it is in driving brads (left) or staples (right) to the same depth. The taller brad in the photo at left is one of the easier to clear jams we had. Click images to enlarge |

|

While the Harbor Freight #40116 tended to overdrive brads (and staples) in pine or poplar, that is not a big problem. We expect a dent/hole needing filling anyway.

However, when I changed to harder woods, red and white oak in particular, things went downhill from the first shot.

The Harbor Freight #40116 was wildly erratic in terms of the depth fasteners were driven. I would shoot groups of ten brads or staples without changing line pressure or the depth-setting wheel but would get fasteners driven at substantially different depths. Oddly, there was no consistency in terms of depth among the ten shots in that group. Within those ten shots we would see some driven correctly, interspersed with others projecting nearly ¼” above the surface. Those partially driven fasteners could be followed by one that was driven just below the surface.

This range of depths was one of the more common complaints among those offering their Harbor Freight #40116’s to NewWoodworker.com for review.

|

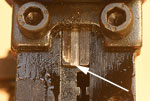

Lousy threads in the air inlet port made installing the coupler more of a job than is necessary. Click image to enlarge |

Along the way I increased the line pressure in 5-psi increments until the upper limit of 100-psi was reached. Groups of ten fasteners (all the same size within each group) were shot at each pressure setting with very little change in depths. Generally, they would be closer to fully driven at higher pressures but the inconsistency remained with some driven fully, others protruding above the surface.

I also tried running the depth adjustment wheel from one end of its travel to the other and shooting a group of fasteners at each of those settings. While there would be a noticeable change in depth corresponding to the change at the wheel, the inconsistency remained. At the full depth setting, the range of depths would be a little closer to the surface of the wood. At the minimal depth setting, the group would be higher overall. In both cases, the range of depths in each group of ten fasteners did not change noticeably.

|

By the end of the evaluation I was getting pretty good at taking the front of the gun apart to clear jams. Click image to enlarge |

I also got rather proficient with taking the front end of the Harbor Freight #40116 apart to clear jams. In pine and poplar I only had one jam. In hardwoods, jams were more frequent, as were “empty” shots where no fastener at all was driven. Over the course of the evaluation approximately 1000 fasteners were installed with the Harbor Freight #40116 and jams averaged 1 in every 90 fasteners fired.

While clearing jams, the entire area surrounding the driving arm and fastener path would be cleaned and lightly oiled. While clearing the second jam, I noticed that the plunger that actually contacts the fastener was already showing wear. The parts surrounding that ram were checked but no cause of the wear, other than contact with the fasteners could be found.

While the magazine seemed to be working fine, I opened it fully, brushed it out and wiped the surfaces down with a lightly oiled rag as suggested in the instruction manual trouble shooting section just in case. That proved to have no effect on the performance of the Harbor Freight #40116.

As a control, I fired the same length and design fasteners at each line pressure setting from my Porter Cable guns each time the line pressure was changed. Those guns performed fine at all of the line pressures and consistently set the fasteners below the surface.

|

This photo was taken while clearing the second jam. I noticed the end of the plunger that actually drives the fasteners was already rounding over. Click image to enlarge |

Though I have never seen a nail gun that had to break in, I continued this evaluation for several days just in case. Each day the Harbor Freight #40116 was oiled and inspected plus the compressor drained and recharged before the test began. From beginning to end, the results were the same.

Conclusions

When I went to buy the Harbor Freight #40116, they had them on sale for $19.99 – and had a couple pallets of them sitting in the isle. I had a hard time believing that I could buy a decent air nailer for $20 and that bit of instinct turned out to be true.

While I believe we should not expect much from a cheap tool, it is my opinion that even at the sale price of $19.99, the Harbor Freight #40116 is dramatically overpriced.

If you only use brads and staples where they will never be seen and you are good with a hammer and nail set, the Harbor Freight #40116 might be a good way to save some money. However, if you like a tool that works as you expect it to, and do that consistently, I would suggest saving money somewhere else.

Note: Though I frequently add updates after using a tool for an extended period of time, there will be no such additions to this review. When I decided enough was enough, the gun was “permanently disabled” with my 10-lb sledge and deposited in the dumpster.

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.