This is a Veteran Owned site

The Delta X5, 14" band saw is very good right out of the box. I wanted to make it better yet. Click image to enlarge |

Hopping Up My Delta X5 Bandsaw

Making very good better

Text & Photos by Tom Hintz

Never being one to leave well-enough alone, I wanted to see how my Delta X5 #28-475X 14" bandsaw would respond to the addition of aftermarket pieces from some of the most respected companies in woodworking. While the Delta X5 is a very good machine as it comes from Delta, I thought the combination of upgrade pieces would make it even better.

On A Roll

|

The Delta mobile base saves the day regularly when I need to use this saw but have other machines in the way. Click image to enlarge |

The first accessory came from Delta in the form of the #50-274 mobile base. Not having the luxury of a large shop, being able to move the Delta X5 cabinet-style bandsaw where space is available just makes sense. The #50-274 mobile base is foot-operated, rolls very easily and is surprisingly stable considering the tall, narrow shape of the bandsaw.

Result

Mobility is especially handy when I need to use the bandsaw in the midst of a project when other equipment is set up and can't be moved easily. Being able to roll the band saw where there is the most room makes it easier to use this machine effectively and safely.

I am reminded of how happy (appreciative would also be a good word) I am with this mobile base every time I have to move the saw, which is often.

Street price for the #50-274 mobile base is $89.95. (12-7-2005) (www.deltawoodworking.com)

See my review of the Delta band saw, including the mobile base.

Delta 6" Riser Kit

The riser kit from Delta gives me 12" of re-saw capacity! Click image to enlarge |

The first change came from Delta in the form of the #28-984, 6" riser kit that increases the vertical capacity to nearly 12". Adding a riser kit is one of the more common bandsaw modifications, particularly with saws in the 14" and larger range. I actually took the bandsaw apart as needed to install the riser kit to make getting the machine out of the shipping crate easier.

The riser kit included everything needed to make the conversion including the block itself, blade guard extension, blade guard post, the rear blade enclosure and a hardware pack that included a very large bolt that holds the top and bottom halves of the machine together. After installing the riser block, I went through the alignment procedures but found virtually no problems.

Result

The riser kit has no affect on the operation of the saw during normal cutting operations. It only becomes evident when a large re-sawing job comes along. I have resawn pieces of oak 11 ¾"-wide with a little vertical capacity left over. The Delta X5 handles those large re-sawing jobs easily, especially when equipped with TimberWolf blades.

The street price for the #28-984, 6" riser kit is $89.95 (12-7-2005) and worth every nickel if you need to re-saw large pieces. (www.deltawoodworking.com)

See my review of the Delta band saw, including the riser kit.

TimberWolf Blades

|

Using TimberWolf blades on my band saw was a no-brainer. They have stepped up the performance of all three saws I have used them on. Click image to enlarge |

Commonly regarded by woodworkers as the best in the business, TimberWolf blades were ordered before this machine arrived. The riser block increased the blade length from 92 ½" to 105" so I called the folks at Suffolk Machine (www.suffolkmachine.com), told them what machine I had, about the riser and asked for suggestions for three blades for general shop use, plus one for resawing. They set me up with four blades that have handled the work in my shop exceptionally well, including large-width re-sawing.

The set of blades consists of a ¼" X 6tpi and 3/8" X 4tpi for general cutting. Also, two of their AS series blades designed for cutting through thick wood, ¾" X 3tpi (AS-S for resawing) and a ½" X 3tpi AS that handles trimming bowl blanks. The prices of the blades ran from $17.20 for the ¼" one to $24.47 for the ¾" version. (5-18-2005)

While this set of blades handles my needs perfectly, TimberWolf may have other suggestions for your situation. My best advice is for you to follow their advice.

In addition to the quality of their blades, the customer service at TimberWolf is second to none. The folks who answer the order-line phones know their jobs, and their blades, very well and will suggest the best blades for your needs. TimberWolf/Suffolk Machine 1-800-234-7297, www.suffolkmachine.com)

TimberWolf blades run at a lower tension than most. Since this saw has a lever-actuated tension system, I had to get a little creative. I found that setting the tensioning system to one blade size smaller than that being used worked very well. I will be looking at add-on hardware that might allow further tension adjustments in the future.

Result

I have used TimberWolf blades on three different band saws and have yet to experience blade drift with them. TimberWolf blades consistently cut easily, cleanly and require less power than any other blade brand or style I have tried. In addition to their performance, TimberWolf blades usually cost less and have always lasted substantially longer in my shop than any other blades I have tried.

See an earlier review of TimberWolf blades.

Carter Roller Guide Conversion

|

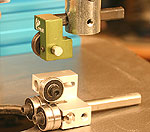

One of the most frequent band saw upgrades, the Carter Roller guides proved their worth. Click image to enlarge |

When band saw owners think of improving their saws, Carter Roller Guides are often at the top of the list. After making the basic changes that affected the blade size, it was time to get rollerized! The factory installed cool block system worked fine but the idea of roller guides just made sense to me.

The Carter Roller Guide Upgrade Kit came with everything needed to replace the cool block system, including fasteners. Carter offers kits designed to fit a huge range of saw models with an extensive application list available on their web site. (www.carterproducts.com)

The installation was far easier than I anticipated, in part because the Carter upgrades replace the entire upper and lower guide assemblies rather than part of them. Remove the factory guide assemblies, install the Carter versions and the saw was ready for final alignments. The process did not take a half hour, including removing the table.

The alignment procedure as described in the instructions was fast and easy. Removing the table makes this an especially simple task on the lower guides though they can be accessed with the table in place on most saws with few problems. The major drawback to adjusting the lower guides with the table installed is seeing what you are doing.

Result

All cutting operations feel more stable and predictable with the Carter Roller Guides. Even when I get carried away and cut curves tighter than I should with a given blade width, the Carter Guides keep the blade surprisingly stable while preventing binding.

Though I have no way to accurately quantify this, my blades seem to run cooler during long cuts than with the standard guides. I am not sure whether the roller guides are preventing some friction related heating or acting as a more effective heat sink, drawing temperature out of the blade. However it is happening, I believe the blades are staying cooler.

The Carter Roller Guide Upgrade kit has a street price of $149.99 (12-7-2005) which makes it even more attractive. (www.carterproducts.com)

See my review of the Carter Roller Guide Kit.

Kreg Precision Band Saw Fence

|

The Kreg Precision Band Saw Fence was easy to install and increased ripping accuracy considerably. Click image to enlarge |

Like many band saws, mine came without a fence. Since I use my band saw for much more than curved cuts, a good fence system was a common sense enhancement. Given the reputation Kreg products have with woodworkers, I decided to use their fence system.

The mounting rail came drilled to fit several band saws, including my Delta X5, making installation very simple. Alignment of the mounting rail and the fence itself were also easy. The Kreg Precision Band Saw Fence can be adjusted on the vertical plane so its face is square to the table (and blade) as well as on the horizontal plane to compensate for blade drift should that be a problem.

I do a fair amount of re-sawing so added the 4 ½"-tall Kreg Re-Saw Attachment that mounts directly to the fence in the upright position. This rounded extrusion makes following a scribed line along the edge of a piece of wood much easier that trying to hold it steady free hand.

Result

The Kreg Precision Band Saw Fence is easy to use and the stick-on scale is spot-on accurate. This makes setting up cuts very fast. I also installed the optional Micro-Adjuster that makes tweaking the fence position to perfect a cut width very easy.

The fence can be used in the upright or laid down positions, allowing the Carter Roller Guides to be placed close to the stock regardless of the thickness being cut. This is an important capability, and one often overlooked when choosing a fence.

With a street price of $109.99 for the Kreg Precision Band Saw Fence, $14.99 for the Precision Adjuster and $17.99 for the 4 ½"-tall Re-Saw Attachment (12-8-2005) this fence system is as good a value as it is capable.

See my review of the Kreg Precision Band Saw Fence.

Visit www.Kregtools.com

Carter Stabilizer

|

The Carter Stabilizer was easy to install and worked better than I thought it could. Click image to enlarge |

When using narrow blades on bandsaw, 1/4" and smaller, conventional guides (block or roller) have very little to grasp to control the blade. Carter Stabilizers cure that problem.

Installing the Carter Stabilizers was fast and easy, in part because it replaces the upper guide assembly and the lower guide is not used.

The Carter Stabilizers sell for $69.99 (12-11-2005) and the Made in America quality, combined with an effective design makes them worth it!

Result

My bandsaw suddenly likes small-width blades! I was able to use a 3/16"-wide blade without it twisting and trying to unwind during the cut. Freehanding a smaller heart inside a small heart was easier than I have noticed before.

See the full review of the Carter Stabilizers.

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.