This is a Veteran Owned site

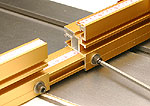

INCRA Miter 1000SE Miter GaugeSuper accuracy, repeatability and priceText & Photos by Tom Hintz Note: I am still (6-5-2011) using my INCRA 1000SE, now 6 years since getting it and I still love it and its automatic accuracy. In the world of aftermarket miter gauges, the INCRA 1000SE is notable because of its combination of high quality materials and innovative design. The real value of any miter gauge is judged by how it affects your work in the shop. On that count –and others - the INCRA 1000SE is an easy winner. Initial ImpressionsVisually, the INCRA 1000SE is impressive in its design and clean, precise machining of the individual components. The fit and finish of the INCRA 1000SE is first rate, as is how its components work together. In addition to the INCRA 1000SE itself, the box contains three labeled bags of hardware for various features and a nice 9 ½"-long, ball-ended Allen wrench for adjusting the fence position and length. InstructionsThe assembly, set up and use pamphlet that comes with the INCRA 1000SE is very well written and illustrated. Many high quality, cleanly printed photos augment the text. Several clear and informative line drawings make understanding the more complicated parts of the text much easier. For example, a full-page insert clearly shows the individual settings of the vernier cursor used to set tiny 1/10th-degree angle changes. Assembly and SetupThe INCRA 1000SE is almost fully assembled as it comes from the box. The user need only replace one hex bolt with the large handle and install the flip-stop assembly onto the rail. Installing the T-slot follower with its single screw is required for saws with that feature. INCRA's ingenious expansion disks make adjusting the guide bar to fit your miter slot fast and easy. After that, squaring the fence base to the table is all that remains. Assembly and setup of the INCRA 1000SE in this review took less than half an hour. Throughout our testing, these adjustments held fast and did not require further attention. Universal Guide BarProbably the most common question I receive about miter gauges is, "Will it fit my miter slot?" The INCRA 1000SE is designed to fit any miter slot between 0.735" and 0.770" in width without machining the guide bar or miter slot. In fact, the guide bar is so unique it is patented and has its own trademarked name - GlideLOCK™! Four pairs of expansion disks are fit along the guide bars length. The bar comes set for standard ¾"-wide miter slots but additional disks are included to fit it to undersized slots commonly found on Sears Craftsman equipment. The guide bar can also be configured to fit oversized slots up to 0.770" in width. The instructions have line drawings showing the configuration for each situation. In the undersized mode, the guide bar can be adjusted from 0.735" to 0.745". The standard setup range is 0.745" to 0.755". With the oversized disk arrangement the adjustment range is 0.750" to 0.770". With the proper disks installed, adjusting the guide bar to the miter slot is a simple matter of turning the expansion disk center screw until side play is eliminated. There is a disk set located under the protractor head, accessed by removing the push handle and rotating the head 180-degrees. It should be noted that the INCRA 1000SE guide bar allows extremely fine adjustment. When moving the adjusted miter gauge along the slot, tight spots may be encountered, caused by slightly narrower portions of the miter slot. A block of ¾"-thick wood wrapped with sandpaper will usually remove the few thousandths of material necessary to correct those slot irregularities. If the INCRA 1000SE guide bar will not fit your miter slot, you have a serious and unique problem. Squaring the fence to the miter slot is the only alignment necessary. Lock the protractor head in the 0 position, loosen the four screws that secure the fence plate and then use an accurate square to align the fence face exactly 90-degrees to the miter slot. Tighten the screws and recheck the alignment. That's it. All other angles are precisely indexed from this setting and require no further adjustments. Protractor HeadLaser cut from heavy gauge steel, the protractor head is at the heart of the INCRA 1000SE AngleLOCK™ system. Around the edge of the protractor head are a total of 43 precision cut and machined indexing notches. There are 20 labeled notches (one every 5-degrees) on either side of 0 and an additional unmarked notch at 95-degrees at both ends. Notches are also included for 22.5 and 67.5-degrees to the left and right. The degree scale on the protractor head is easy to read even with my 50-something eyes. The numbers and hash marks are clearly printed with crisp edges that make aligning them to the vernier cursor an easy task. A key to the accuracy and repeatability of the AngleLOCK™ system is the actuator that mechanically indexes the degree notches the same way every time. The actuator has its own pivot and locking knob so the tooth that engages the protractor head notches can be locked in a notch or away when custom settings are required. The label affixed to the center of the protractor head has a handy table listing the angles necessary for making circles with 4, 6, 8, 9, 12 and 18 segments. The accuracy and repeatability of the INCRA 1000SE make this once trial-and-error intensive task far easier. Vernier Cursor

Mounted on the actuator, the vernier cursor scale allows changing angles by as little as 1/10th of a degree accurately. The vernier cursor can be pivoted back out of the way when not in use or locked in the forward position to align its markings with those on the protractor head. The vernier cursor looks complicated to use but really is not. Once you understand the premise, making these tiny angle changes is surprisingly easy. To help that understanding along, INCRA includes a full sized sheet in the instructions with diagrams of each vernier cursor setting from 0 to 9/10-degree of change. Expandable Fence

Formed from a heavy-walled, multi-channel aluminum extrusion, the INCRA 1000SE fence is very straight and extremely rigid. Fence to blade clearance can be adjusted easily but has its liabilities. When pivoting to the right, the fence can move into the blade path. Be sure to check for sufficient clearance between the fence and blade before making a cut! The fence measures 18 ¼"-long (closed) with a 1 ¾"-tall forward face. A 4"-long section extends to a maximum of 31" on a rigid 5/8"-tall by 1 ¼"-wide bar. Repositionable scale inserts along the top of the primary fence and the extension bar can be set so they are accurate with most fence-to-blade clearances. The front of the fence has T-slots that can be used to mount a wooden auxiliary face. Instructions and hardware for mounting a shop-made auxiliary face are included with the INCRA 1000SE. Flip Stop

INCRA designed a very solid, easy to use adjustable stop mechanism they call the Flip Shop Stop™. The INCRA 1000SE flip stop is positioned along the top of the fence, locking into a finely serrated strip that makes it rock solid using only finger-tightened screws. In addition, super fine blade-to-stop adjustments are available using a screw positioner that works independent of the serrated strip. The INCRA flip stop has two arms that can be locked together with the included bar, or used independently with any combination of the long bar or two shorter bars, also included in the kit. Both flip stop arms have "teeth" that lock into the face of the fence when in the down position. The flip stop arms can also be moved to a forward mounting channel for use with a ¾"-thick auxiliary fence in place. Both of the adjustment systems remain accessible with the arms mounted in the forward or back positions. In The Shop

As is my practice during these tests, the saw blade and fence were checked to be sure they are parallel to the miter slot and would not adversely influence the performance of the INCRA 1000SE. The first test was cutting a 8"-wide board at 90-degrees and then standing it on edge, the cut off piece flipped top-to-bottom to check accuracy. The pieces fit together perfectly indicating the fence was exactly 90-degrees to the blade and miter slot. Subsequent cuts at any angle I could think of produced the same results – dead on accurate – checked with my Bosch Digital Angle Finder. To check repeatability, a 22.5-degree cut was made and checked, followed by several cuts at other angle settings. Returning the INCRA 1000SE to the 22.5-degree notch produced another precise 22.5-degree cut. Cutting long pieces with the fence extended feels solid and produces very accurate cuts, straight or angled. During testing, boards over 6-feet-long were cut with no sensation of impending loss of control. Though the INCRA 1000SE was used extensively, the initial setup of the guide bar and fence did not change. The fit to the miter slot remained snug and movement of the miter gauge across the table smooth. The plastic shoe under the protractor head and an anti-friction strip along the bottom of the primary fence reduce drag and prevent scratching of the table surface. The flip stop proved to be solid in all configurations. Being able to split the two arms for use independently comes in handy when more than one length board has to be cut for a project. This feature would be especially handy when making several copies of projects such as picture frames or boxes requiring two different lengths. Regardless of the need, the flip stop is easy to adjust with extreme accuracy and then holds that position until you move it. When odd angles have to be matched or small corrections needed, the vernier cursor saves the day. Being able to change an angle by as little a 1/10th of a degree with absolute accuracy lets you match cuts precisely and know exactly how much of a change was required. This can be valuable information should this cut need to be repeated in the future. ConclusionsThe INCRA 1000SE is an extremely accurate and versatile miter gauge that will improve your woodworking at a surprisingly low street price under $150! Top quality materials and manufacturing insure repeatable precision that means you will make more cuts right the first time and every time after that. You concentrate on the project and not what the miter gauge was supposed to have done. Do you have a comment about this page? - Email Me! |

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.