This is a Veteran Owned site

|

The JET Tenoning Jig is heads above the dollar-saving no-name junk. But you already knew that, or should have anyway. Click image to enlarge |

JET Tenoning Jig

25-Lbs of nicely crafted cast iron for accuracy and safety

Text, photos and video by Tom Hintz

Posted – 7-18-2011

One of the first table saw kickbacks that I witnessed came when a highly experienced career cabinetmaker was making a tenon cut at his trusty table saw using a beautifully made wooden tenoning jig. He had made several tenon cuts as we watched but then something went wrong, I heard a loud “bang” and the piece being cut and the jig to which it was clamped shot off of the table surface and hit the cabinetmaker on his right jaw and shoulder with enough force to knock him a step or two away from the saw.

Though the tenoning jig he had made was very well done, it lacked the simple mass and interlocking grip in the T-shaped miter slot. That left only his hand to prevent his jig and the wood clamped to it from being kicked out at the operator. Things like that stick in my head – hopefully before something sticks INTO my head!

The Basics

The JET JTG-10Q (#7082965) Tenoning Jig is nearly all cast iron which explains its 25-1/2 LB mass. While that weight alone will counteract many kickbacks this jig also features a steel miter slot guide rail that is equipped with a T-slot disk that prevents the jig from tilting back or lifting out of the slot. This rail fits the very common 3/8”-deep by ¾”-wide miter slots found on virtually all full-sized table saws. The JET Tenoning Jig is 9”-tall, 12.6”-wide and 12.2” long.

|

|

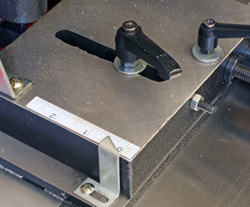

The steel guide rail (left) has a t-slot follower that prevents the jig from being lifted out of the miter slot. There are also two mounting positions to accommodate most full-sized table saws.The heavy cast iron base (right) has an easy to read scale for basic setups. Click images to enlarge |

|

The cast iron base has two mounting positions for the all steel miter slot follower. Naturally the JET Tenoning Jig fits most JET and Powermatic saws but the dual guide bar mounts mean it also fits most other full-sized table saws as well. The base has easy to use adjustments to be sure the stock-mounting table surface is parallel to the blade and to lock out the travel so you cannot accidentally adjust the JET Tenoning Jig into the blade. That would be exceedingly bad ca-ca.

The JET Tenoning Jig features a 5-3/4”-tall by 5-1/8” wide cast iron table to which the stock is clamped. This table can tilt about 23-degrees left (operators perspective) and it also has a vertical stop that can be tilted up to 45-degrees back. This stock table is remarkably solid due to its impressive mass but also the oversized hinge at its base. Tighten the repositionable locking handles and this table is not going to change settings until you intentionally do it next time.

Micro and Fast Adjustments

The JET Tenoning Jig has a micrometer-like fine adjustment that lets you tweak the position of the material in relation to the blade in tiny increments. This is important because of how small the final adjustments often are as you approach the perfect cut. Release one locking handle and you can dial in the adjustment you need precisely. An easy to read scale with correctable pointer helps more with coarse setup than the final cuts but still makes the job go faster.

|

|

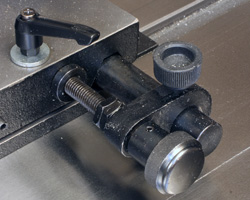

The coarse and fine adjustments (left) make this a very easy jig to use with exceptional accuracy. This jig also has independent bevel and miter angle features (right) that let you make virtually any kind of tenon. Click images to enlarge |

|

When large adjustments are needed the JET Tenoning Jig has another knob that when released lets you slide the entire upper base (and the fine adjustment system) to where you need it. Re-tighten this knob and you can go back to the micrometer setting to dial in the exact setting needed. Both the coarse and fine adjustment systems are very quick yet very precise. That lets you get more work done with fewer headaches.

Versatile Clamping

The JET Tenoning Jig has a nicely made clamping wheel that turns a shaft made with Acme threads that produce big clamping pressures quickly with minimal effort. These threads also tend to shed sawdust very easily to avoid binding up. The end of the threaded rod is fitted with a large-diameter steel flange that is fitted with a non-marring cover that applies the pressure over a larger area than most others in this type of jig.

A nifty feature of this clamping system is a front to back adjustment that allows applying clamping pressure where it works best on the stock. A simple locking lever releases a hefty shaft that lets you move the clamping screw forward and back as needed. Get it where you want it tighten the locking lever and the JET Tenoning Jig is ready for work.

|

|

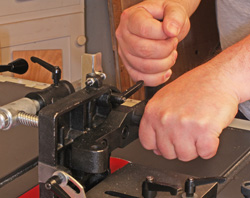

The Acme threaded clamping screw (left) can be repositioned to apply plenty of clamping pressure where you need it. The dual handles (right) keep your hands on the correct side of the jig and out of harms way. Click images to enlarge |

|

Big Handles

The JET Tenoning Jig has two large push handles that make controlling this 25-lb jig easy. Since these handles keep your hands away from the blade they are a major safety factor as well. The forward handle has two mounting positions that lets the operator set up the JET Tenoning Jig for the best, most comfortable feel for you.

In the Shop

Over the years I’ve had two or three of the no-brand, low-buck table saw tenoning jigs. When I unpacked my new JET Tenoning Jig it was immediately apparent that JET was taking advantage of its big kid on the block status and was brazenly cheating within this little segment of the woodworking market. Not only did JET produce parts that actually fit and function as designed, they shamelessly included a well-written and illustrated instruction manual in the box that shows how to adjust and use their (better) table saw tenoning jig. The nerve of some people’s children.

After going through the JET Tenoning Jig looking for loose fasteners (there were none) I followed the illustrated instructions showing how to set the jig parallel to the blade and how to set the adjustable stop so you can’t accidentally over adjust the JET Tenoning Jig into the table saw blade. After those simple checks using the JET Tenoning Jig is really very intuitive.

I especially like the fine and coarse adjustment system. The coarse function is good for rough setting the jig for the size lumber being used. From there the fine adjustment feature lets you dial in a perfect fitting tenon that repeats very well if your lumber is consistent in thickness. The whole idea behind a jig is to make producing many identical pieces easy and with the JET Tenoning Jig it actually is easy. What a concept!

|

|

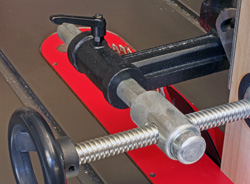

This single lever lets you move the clamping screw (left) forward or rearward to put the clamping pressure right where you need it. JET includes a fully illustrated, easily u8nderstood instruction manual (right) that is much like them kicking the other manufacturers while they are down. Click images to enlarge |

|

Another very nice touch is the Acme thread on the clamping shaft. I also like the large diameter pressure disk and its no-mar cover. The relatively small diameter wheel that is used to apply clamping pressure really is large enough to secure the workpiece tightly.

What makes this clamping system better is that it is mounted on a heavy-duty shaft that lets you position the pressure disk where you need it on the stock you are working with.

Using a single locking lever is all that is needed to reposition the clamping mechanism. Another twist of that locking lever and your setup is ready for use. This is a nice system that makes the JET Tenoning Jig a little better in one more way over the competition.

The JET Tenoning Jig does the bevel and angle tenons as well but for most of us the vast majority of our work is cutting accurate thickness tenons, making them quickly and doing both safely. The snug-fitting steel guide bar, the t-slot follower and the 25-lb mass make the JET Tenoning Jig a very safe tool. Even the placement of the dual (and large) push handles positions the operator where you should be out of the way if things actually do go wrong at the blade.

Conclusions

Video Tour |

The JET Tenoning Jig is well made and thoughtfully designed for real-world woodworkers. In this segment of the woodworking marketplace just including an instruction manual that can actually be read and used often puts a product at the head of the pack. In the case of the JET Tenoning Jig, that manual and a full range of easy to use features make the JET Tenoning Jig a tool that is well worth owning.

With a street price of just $168.00 (7-18-2011) the JET Tenoning Jig is not out of reach for the average woodworker. If you want to make quality, good fitting mortise and tenon joints the JET Tenoning Jig should be at the top of your must-see list. I have been using the JET Tenoning Jig shown in the accompanying photos and video for a few years now and it remains a nice tool to bring out. Setup and adjustments are easy and it does what it was intended to do accurately. There are a bunch of tools out there that you simply cannot say that about!

Have a comment on this review? Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.