This is a Veteran Owned site

|

|---|

Notice the screw-on caps that work so well I nearly forgot all about having to fight to get CA glue out of its bottle. These glues work well as do their caps! Click image to enlarge |

Nexabond™ 2500 Wood Adhesive

CA glues that defy humidity

Text, photos and video by Tom Hintz

Posted – 4-30-2014

A common trait among woodworkers is the desire to adhere pieces of wood together quickly and permanently. It should not surprise us to find a new entry to that marketplace in the form of Nexabond™ 2500 Wood Adhesives. What did surprise me about Nexabond™ 2500 Wood Adhesive was that while they understandably touted their new (to me) product their PR spiel lacked the over the top, pie in the sky platitudes that relegate so many professionally prepared press releases to the ho-hum file. The Nexabond™ folks appeared to be focused on gluing stuff together and that piqued my interest.

The Basics

Nexabond™ 2500 Wood Adhesive is in fact cyanoacrylate glue that comes as a clear liquid and is available in three formulas, 2500M is the Instant variety, 2500S has what is called a “Short Handling Time” and 2500L is the “Long Handling Time” version. All are said to be water-free and all claim to work at any humidity without an activator. What was more interesting was the “any humidity – same speed!” line from their literature. Now that is different.

In case you were wondering, yes the wood needs to be dry and dust free, yes the joint has to fit properly and yes you have to clamp the pieces up. You don’t get to slack off on the woodworking skills, just some of the time expended. The good news is that they call for clamping in most cases for “a few minutes” and say the maximum strength is achieved within 8 hours.

|

|---|

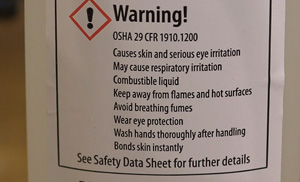

Nexabond remains a CA glue that requires all of the precautions we are supposed to take with this stuff plus this material is flammable. Click image to enlarge |

They repeatedly say to use small amounts of Nexabond™ 2500 Wood Adhesive because they have obviously watched woodworkers assemble things with glue dripping all over the place. You really want to get a grip and use reasonable amounts to get the most benefit from Nexabond™ 2500 Wood Adhesive. They also say the shelf life of Nexabond™ 2500 Wood Adhesive is 12 months at 72-degrees.

With all of its good qualities Nexabond™ 2500 Wood Adhesive remains CA glue and still adheres your skin to itself and other stuff very well. Using this glue requires all of the normal safe handling precautions we should be using with any material of this type. Read the container and packaging!

In the Shop

There are tightly controlled procedures for testing adhesives but I am doing this in my shop so we are going to settle for real-world conditions. When I get to do woodworking in a lab we can be more scientific. The good thing about this is that you don’t work in a lab either so maybe some of my real world will align with your real world and we can get an idea of how the Nexabond™ 2500 Wood Adhesive works in our real life woodworking shops. My primary goal is to be consistent with all of the Nexabond™ 2500 Wood Adhesive variations and all of the sample glue joints. Of course if it doesn’t work they will say this is all ca-ca but let’s see how it does.

I cut up a bunch of pine strips, some poplar and a pair of oak mitered pieces. I applied what appeared to be a decent amount of glue over a roughly 1” square surface on one piece ad then clamped the two pieces together for 5 minutes. After the 5 minutes had elapsed I took all of the pieces out of the clamps and set them aside for 8 hours. I also had marked three of the pine assemblies with the version of Nexabond™ 2500 Wood Adhesive that was applied.

|

|

|---|---|

All of the samples were clamped up (left) for 5 minutes then the clamps removed and they were left to cure for 8 hours. The Instant version pulled a good bit of wood from the opposite side (right) showing the wood failed before the glue over most of the joint. Click images to enlarge |

|

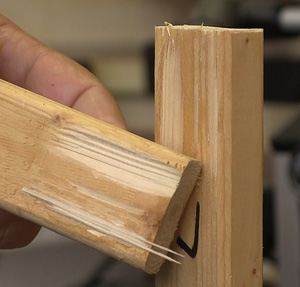

Eight hours later I put one leg of the pine strips in a vise and jerked on the other end to break the joint. There was no illusion that a little glue was going to resist breaking, no glue will. The point was to see if we would get tearout when the joints failed which indicates the failure was in the wood, not the Nexabond™ 2500 Wood Adhesive.

I should also note that it took more force to break the joints than I expected. To be honest I anticipated the center of the glue joint to still be somewhat uncured after 8 hours but that didn’t happen. That meant that I had to break the entire joint, not just the periphery.

Of the three varieties of Nexabond™ 2500 Wood Adhesive the Instant version showed the least pull out as would be expected in many woods. In something like balsa where the glue can instantly wick into the fibers more deeply lots of tearout is likely. In the pine I think it did well with a good amount of wood separation despite what looks like insufficient coverage of the joint on my part when I applied the glue.

The 2500S, short working time version did a bit better, again as anticipated. When a glue cures slower in most cases that time allows it to penetrate the wood better and get hold of more fibers. The 2500S did just that and pulled more wood out of the opposite sides of the joint. Here again I think I could have applied a bit more glue to better cover the area the Nexabond™ 2500 Wood Adhesive did a good job nonetheless.

|

|

|---|---|

The medium version (left) tore more wood out showing more penetration. The slow setting type (right) shows the most tearout as we would expect among these samples. I fully expected this version to have wet glue at the center of the joint after 8 hours but none is present. Click images to enlarge |

|

The 2500L Nexabond™ Wood Adhesive did the best in this test, literally pulling a good-sized chunk of wood out of the other piece when the joint failed. In this case I actually applied too much Nexabond™ 2500 Wood Adhesive and there was a good amount that squeezed out on one side that was not fully dry after 8 hours. The excess had gotten rubbery but everything within the joint appeared cured, further evidenced by the large amount of pullout within the joint.

I also did a couple samples of poplar, glued with the Nexabond™ 2500S Wood Adhesive mid-range short working time version. I also clamped these samples for 5 minutes and broke the joints 8 hours later. Lots of tearout appeared on both of the samples. I suspect the poplar was considerably drier than the pine, plus poplar soaks up glue pretty well so the Nexabond™ 2500 Wood Adhesive penetrated well and did a good job of bonding the pieces together.

Just for grins I used the Nexabond™ 2500S Wood Adhesive to glue two pieces of poplar together end grain to end grain. Naturally the joint failed but under magnification you can see a bit of tearout where the glue snapped off of one side. I suspect that these very short pieces of tearout were fractured bits of grain that may have been damaged during cutting. If this or any glue would have held in end grain we’d have a much bigger story here!

I also tried gluing a mitered corner that is again largely end grain though the fibers are cut on a bias. This is still a lousy joint to glue and I was able to break it with a bit of force. Here again I was not expecting a show of holding strength because of the end grain. Nexabond™ 2500 Wood Adhesive is good stuff but not magic.

Video Tour |

|---|

Conclusions

Nexabond™ 2500 Wood Adhesive appears to be a very good line of CA glues that are not affected by humidity as their literature claims. My break tests though admittedly not scientific are real-world based and show Nexabond™ 2500 Wood Adhesive has joint strengths at least equal to any CA glues I have used. I expect that once you get used to the amount of glue that needs to be applied the strength will increase even more.

Throughout testing something about the Nexabond™ 2500 Wood Adhesive packaging almost escaped me because it never became an issue. The screw on caps have not become loaded or clogged with glue buildup. They worked so easily throughout my in shop testing that I nearly overlooked them. If you have fought with stuck caps or even ruined a good bottle of glue trying to get it out of the container is no small issue and a big plus for Nexabond™ 2500 Wood Adhesives.

Nexabond™ 2500 Wood Adhesive glues have a street price (4-29-2014) of $7.99 for one ounce bottles to $16.99 for four ounce bottles. Add that to the ease of getting the bottles open after the initial use and the cost per use with Nexabond™ 2500 Wood Adhesive could be substantially less than many other CA glues. That is also a big plus for those of us who lack unlimited woodworking budgets.

Visit the Nexabond™ 2500 Wood Adhesive page at Rockler – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.