This is a Veteran Owned site

|

The Rockwell Bladerunner isn't a table saw and it isn't a jigsaw but it is an interesting machine with unique capabilities. Click image to enlarge |

Rockwell Bladerunner

An old idea in modern clothing

Text, photos and video by Tom Hintz

Posted – 10-2-2010

Remember when there were just table saws and jigsaws and occasionally someone would try hanging a jigsaw upside down in a table? Well, enter the Rockwell Bladerunner and we see that the initial concept was good all along. What it needed was to be thought out in modern terms from the ground up and Rockwell took on the challenge. Rockwell is obviously not trying to replace a real table saw or a real jigsaw but this combination has definite possibilities for a subset of today’s woodworkers.

The Basics

The Rockwell Bladerunner is a bench top machine and I think sized right for that use. The table surface is 15-3/4” wide by 17”-deep. The table surface is 9-1/4” above the surface that the machine is set on. The table surface is made from brushed steel panels with inset T-shaped slots that accept the included miter gauge. One slot runs front-to-back and a second running side-to-side with both going all the way across the table. The case sits on rubber feet in the corners that help keep it in place and reduces sound transmissions.

While the corners of the table are clipped at a 45-degree angle the rest of the table edges are square. That makes it possible to use aftermarket clamp-on fences or shop-built jigs for ripping or other specialty operations.

|

|

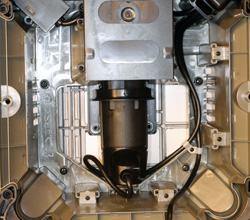

The motor (left) is under the table and has plenty of power for this application. The over arm guard (right) is effective as is the dust control. Click images to enlarge |

|

The Rockwell Bladerunner has an over arm blade guard with a built-in dust port. The guard is pretty rudimentary but does work and can be adjusted up out of the way for blade changing or at any height in between to accommodate various material thicknesses. A lever-operated pressure foot helps keep the workpiece down on the table. The dust port is also pretty simple and includes a twist-in connector with a 1-1/2”-diameter end that fits common shop-vac hoses. The dust system actually does a pretty good job when you can work with the guard down.

The Rockwell Bladerunner is driven by an internal 5.5 Amp, 120V motor that produces blade SPM (strokes per minute) of 800 to 2800 with a 7/8”-long blade stroke. A speed control dial is built into the left front corner of the case. A keyed ON/OFF flip-type switch is mounted in the right front corner. Remove the plastic key and the switch is disabled to prevent unauthorized (inquisitive children and adults) while you are not present or using it.

When equipped with the correct blade for the material the Rockwell Bladerunner is versatile. It is capable of cutting wood up to 1-1/2”-thick and PVC pipe up to 1-1/4”-diameter. Put a metal-cutting blade in and the Rockwell Bladerunner can handle aluminum up to 3/8”-thick and steel with a maximum thickness of 1/8”. You can even cut ceramic material up to 7/8”-thick with an appropriate blade.

|

|

The cabinet (left) has built-in blade storage and a dust drawer. Changing blades (right) is fast and tool-free. Click images to enlarge |

|

The cabinet has cord storage pegs in the rear and a pull-pout dust drawer at the bottom of the front panel. Just below the table, also on the front is a pullout blade storage drawer with holders for several blades. The blade drawer has a magnet built in that helps hold the blades in place during transport.

The case of the Rockwell Bladerunner has a carry handle that make it easy to take it where you need it or to store it when you are done. With an overall weight of just 17.6-lbs you won’t need to build a cart to move it around.

Blades and Changing

The Rockwell Bladerunner uses the hyper-popular T-shank style blades so the available selection is virtually endless as is their availability. I would however strongly urge you to use good quality blades in this machine to get the most out of it. The Rockwell Bladerunner comes with five sample blades with one each for wood, scrolling wood, aluminum, “metal” (steel etc.) and a ceramic blade.

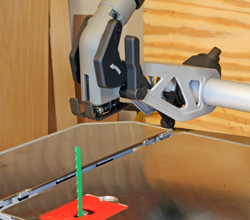

Blade changes are tool-free thanks to a slide button set into the table surface. Depress a red button and slide it to the right and the blade is released. Insert the new blade through a rubber seal that protects the blade mechanism below. Make sure that the blade is fully seated and release the slider button lock and it is ready to use.

|

|

The over arm guard (left) can be adjusted to accommodate the wood thickness or to be out of the way for blade changes. The Bladerunner comes with a miter gauge (right) that pivots to both sides, has an adjustable fence and can be locked in the T-shaped slots but if accuracy is the goal, think about building a sled. Click images to enlarge |

|

In the Shop

It is important to note that if you are looking for a bench top miracle to replace a table saw, the Rockwell Bladerunner is not it, is not advertised as one and there really isn’t such a miracle machine anyway. However the Rockwell Bladerunner is a well thought out improvement on the old idea of hanging a jigsaw under a table.

After assembly I made basic cuts using the supplied blades. While they do work I quickly found that you can help the Rockwell Bladerunner a bunch by using high-quality, aggressive blades. I used some mean looking Bosch blades and the performance perked up a bunch. The included miter gauge is OK but if you want to make accurate rip and cross cuts I would suggest building a sled. Just as on full-sized table or band saws, a sled improves accuracy and cut performance. The metal blade that came with the Rockwell Bladerunner did a good job on some 1/8”-thick steel angle that I tried cutting.

The over arm blade guard works and takes just a little getting used to in terms of setting it up right. The dust collection with my DC hooked to the outlet is very good. Some saw dust still found its way onto the top of the machine but not much at all considering the cuts I was making.

The speed control is handy when changing to different style blades or working with different materials. The motor has plenty of power when you use reasonable feed rates and good blades – both of which you should be doing anyway regardless of the available power.

Where the Rockwell Bladerunner really shines is when equipped with an aggressive scrolling-type blade. Being able to have the work flat on the table and using both hands to steer it just feels way better than when using a hand-held jigsaw or even a real scroll saw. Certainly the Rockwell Bladerunner can’t match the really fine work a scroll saw is capable of but with the right blade it can come close.

Circle Cutter Accessory

Note: The over arm guard and dust collection assembly has been removed for visual clarity for both accessories.

This accessory gives the Bladerunner the capability to cut perfect circles from 3” to 18” in diameter in material up to 1”-thick. The Circle Cutter slips into the front-to-back miter slot and uses a latch that fits into the left-to-right miter slot to lock it the jig in place. That latch also lets you start with the jig and material pulled towards the operator and then with the Bladerunner operating slid forward to engage the blade so you can cut the circle in a piece of stock that is slightly larger than needed to insure a fully round work piece. The Circle Cutter kit (RW9261) includes the jig itself, a center pin fixture with screws and a scrolling-type blade capable of cutting the full range of circles.

|

|

The Circle Cutter Kit (left) actually does a good job of cutting circles accurately. I cut four different sized circles and all came out at the right size and round! Not all circle jigs can say that! The Picture Frame Cutter (right) is going to take some effort to get it cutting accurate miter joints. Its fit in the miter slot is a bit loose and that lets the entire jig rock back and forth horizontally. I think this jig could be made to work right but this is taxing the capabilities of this saw. Click images to enlarge |

|

To use the Circle Cutter cut the stock slightly larger than needed and mark the center with crossing lines from each corner. (Using square blanks is easiest) Place the center pin fixture over the intersection of the lines and use the included ½”-long screws to secure it. Install the included scrolling blade in the Bladerunner.

With a Phillips screwdriver set the pivot point on the jig to the size wanted and then tighten the screws to lock it in place. Slip the jig into the miter slot but stop well short of the blade. Place the wood and pivot fixture on the Circle Cutting jig making sure that the pin goes into the pivot point on the jig. Start the Bladerunner and slowly push the wood forward until the latch on the Circle Cutter clicks into the left-to-right miter slot. Then slowly turn the wood to cut the circle making sure to hold it down to keep the center pin engaged. When the circle is complete shut the Bladerunner off before removing the work piece. Remove the pivot fixture and the circle is complete.

Picture Frame Cutter Accessory

The Picture Frame Cutter fits into the front-to-back miter slot and uses two prepositioned faces to hold stock 45-degrees to the blade. The jig includes the base jig, an extension arm and an adjustable stop. The fence surfaces have a rubber strip that helps to prevent creeping during the cuts. The Picture Frame Cutter can cut components up to 26”-long and in material up to ¾”-thick.

To use the Picture Frame Cutter place the material against the front (operator side) fence and make the first cut. Depending on the length of the wood you might have to install the extension arm. Set the stop to the length the component needs to be. Move the stock to the rear face and put the end just cut on the front face of the jig against the stop and make the second cut to finish that piece.

The kit also includes something called a “rebate pointer” that helps set up for cutting frame pieces with rabbet for a backing board.

Conclusions

Video Tour |

The Rockwell Bladerunner is an interesting saw with capabilities that will suit many woodworkers that live with a small workspace or that enjoy making small projects or smaller project pieces. It has plenty of power and runs on normal household current which can also be important for many woodworkers.

With a street price of $159.95 (10-01-2010) putting a Rockwell Bladerunner in your shop is economical as well.

Visit the Rockwell web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.