This is a Veteran Owned site

|

|

The Woodpeckers’ Side Winder Router Lift represents another first class tool from the folks in Ohio who prove that making good stuff in this country is not impossible! Click the image to enlarge |

|

Woodpeckers’ Side Winder Router Lift

Fine-tuning perfection from the outside

Text, photos and video by Tom Hintz

Posted – 10-2-2011

It’s no secret that I have been a fan and user of Woodpeckers’ router lift plates for years. I just love things that work so well, are so durable and are made with so much precision in the United States. The often-innovative design of Woodpeckers' products is no small instigation either. Well, the folks at Woodpeckers’ have raised the bar in the router lift world once again with their Woodpeckers’ Side Winder Router Lift. I thought the PRL-V2 just might be the best router lift ever but I should have known better when dealing with Woodpeckers'.

The Woodpeckers’ Side Winder Router Lift incorporates much of the shop-proven technology from their famous PRL lift series including the quick lift system and over the top rugged motor mounting mechanism. All of the traditional Woodpeckers’ ultra-precise CNC machining and top-shelf materials also made the jump to the Woodpeckers’ Side Winder Router Lift.

|

|

Everything about the Woodpeckers’ Side Winder Router Lift is heavy duty from the 3/8"-thick surface plate (left) to the oversized motor carriage beneath it. This is a true above table bit changing lift! (right). |

|

The Woodpeckers’ Side Winder Router Lift is available in two models. The SW350 model is designed to handle the smaller 3-1/2” diameter motors without requiring adapters. Included are the Porter-Cable 690/890 series motors, Bosch 1617/1618 and Craftsman models 17542, 17540, 28190. The SW420 was designed around the tough V2 carriage which can accept the Porter-Cable 7518, Milwaukee 5625 and the motors in the 3-1/2” diameter group that fit the SW350 with the installation of the correct mounting pads. Other router motors may also be compatible so check with Woodpeckers’ to be sure if your router is not listed here.

Solid Base

The Woodpeckers’ Side Winder Router Lift is built around a tough 3/8”-thick, high-quality aluminum plate that fits the common 9-1/4” by 11-3/4” by 3/8”- deep openings very closely. The thickness and quality of the plate material allow it to support the larger router motors without fear of sagging now or in the distant future. Two height-adjusting screws on each side of the plate let you dial it in flush with or just a hair below the table surface. Because bits are changed above the table Woodpeckers’ added under-table clamps that secure the plate in the recess to insure maximum stability of the bit during use. A steel starting pin is also included and can be inserted in four positions around the bit to insure flexibility and safety.

The Woodpeckers' Side Winder Router Lift comes with three insert rings to size the opening for the router bit diameter being used. Included are a 1-3-16” stepped insert for the popular Porter Cable style guide bushings and inserts with 1” and 2-5/8”-diameter openings. These are very precisely made high-quality plastic inserts that fit the opening very closely. They use the Woodpeckers' Twist Lock design and come with a special wrench for installing and removing them. There are rumors spreading around that these inserts are cheap and made in the Far East. Once again the Internet got it all wrong because these inserts are very well made and Made in America.

Motor Carriage

|

|

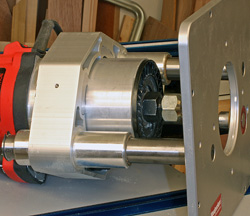

The "shoe" system (left) keeps the router motor solid in the carriage. To keep the entire carriage assembly moving straight up and down Woodpeckers' uses these tough 1"-diameter (right) ground steel columns. Click images to enlarge |

|

At the core of the Woodpeckers' Side Winder Router Lift is the massive, CNC machined boss that secures the router motor. Where other router lifts may be sufficient the Woodpeckers' Side Winder Router Lift is decidedly over built. The carriage itself is huge but it also runs on two 1”-diameter, precision ground columns. The carriage has large bushed sleeves that run on the columns and eliminate play in any direction I could find. These bushings extend above and below the carriage itself to virtually eliminate deflection of the motor carriage under the pressure of routing wood.

The router motor is secured by three heavy pads that each grip the motor at two points to lock it securely and eliminate play. Once you install the motor it only comes out when you take this stuff apart. If you followed the instructions any movement of the motor is a red flag that you have done something very wrong during the installation.

Lift & Adjust

The Woodpeckers' Side Winder Router Lift features the patented Woodpeckers' Quick-Lift system that uses a spring-assisted rod to make large height changes of the bit height very quickly. Insert the rod through the hole in the plate surface and into the boss in the motor carriage, give it a quarter turn and you can move the motor up or down to any point in its range. That includes bringing the motor fully up to make bit changes above the table.

After putting the motor at the approximate height needed you can use the side-mounted crank to fine tune the bit height quickly and easily. Each full turn of the side crank produces a height change of 1/32”. To help make ultra-precise bit height changes Woodpeckers' includes a repositionable scale on the table surface that features graduations that are 0.001” apart. Because those markings have a bit of separation between them it is not hard to go half of a thousandth and be very close to perfect. Once set you can reset the dial to zero to allow increasing or decreasing the bit height exactly as needed. If you can’t make virtually dead on cuts with the Woodpeckers' Side Winder Router Lift you are not trying.

|

|

After rough-setting the bit height with the Quick Lift, the new crank (left) lets you dial in the precise bit height needed. the repositionable scale wheel (right) has graduations showing 0.001" of height change. If you can't get it right with this system, you need to go wait in the bus. Click images to enlarge |

|

The crank mechanism is mounted on the side of the table where reaching it while watching the indicator dial or the bit itself is surprisingly comfortable. When I first saw the Woodpeckers' Side Winder Router Lift I was a little concerned about the locations of these controls but that turned out to be unfounded. Woodpeckers' obviously had figured this out in the real world because it works great and feels very natural.

The bracket that locates the crank handle bolts right up to Woodpeckers' router tables but is easily adapted to virtually any table with relatively common dimensions. The instructions explain the installation very well and may involve drilling two holes. The Woodpeckers' Side Winder Router Lift kit also includes nice hardware for mounting the plate.

In the Shop

I installed the Woodpeckers' Side Winder Router Lift in my Kreg Precision Router Table and the sizing was dead on - literally a drop in job. I leveled the Woodpeckers' Side Winder Router Lift with the table surface and was able to get it between absolute flush and 0.001” below the table surface. I like this setting as it insures that the wood will pass over it smoothly without catching or dropping.

I left the under-table locking blocks free for the time being and moved on to installing the crank handle and hardware. Again, nothing to it. I did have to drill a couple holes (not required on Woodpeckers' tables) but that went quickly and the included very low profile, flat head bolts secured it tightly without anything sticking up to skin my knuckles on while making adjustments. When I was satisfied with the installation I tightened down the under-table locks. Because the Kreg Precision Router Table does not have the usual lip around the opening the locking blocks only grab on one corner but that has proven to be plenty and they have remained snug. The close fit of the Woodpeckers' Side Winder Router Lift to the cavity in the Kreg table makes the under table clamps a non-issue.

|

|

Click on the image to the left to see Made in USA that is precisely included in the new high-strength plastic inserts. This lift also comes with a steel starting pin (right) that can be installed in one of four positions. Click images to enlarge |

|

The first operational test I did was to put a flat-bottomed bit in the Milwaukee 5625 router and then set it ¼” above the table surface. I zeroed out the dial scale on the surface of the Woodpeckers' Side Winder Router Lift plate and the put my Oneway Multi-Gauge on top of the bit and zeroed it out as well. I carefully turned the Woodpeckers' Side Winder Router Lift crank to move the dial 0.008” and then checked the Multi-Gauge and it showed 0.0085”, or around ½ of a thousandth off. Closer inspection of the dial suggests that I stopped the adjustment on the high side of the 0.008” has mark. I’m willing to bet that if I can keep errors down to ½ of a thousandth of an inch this easily you can also. I also discovered that when you miss a hash mark on the scale wheel by so little, bumping the crank handle will let you perfect the setting before locking the bit height in place.

I set the bit height to ¼”, locked the Woodpeckers' Side Winder Router Lift handle with the locking screw and then set my Multi-Gauge on it and zeroed the dial. I then made a couple 18”-long cuts to see if the Woodpeckers' Side Winder Router Lift would hold its height. I put the Multi-Gauge back on the bit and found that the Woodpeckers' Side Winder Router Lift had not moved at all. I later tried this same thing but made 9 18” cuts (that’s when I ran out of scraps) and again, the bit height remained unchanged.

Over the course of this test I made all of the cuts I normally make in my shop and some that I much more seldom. I used the included steel starting pin and found that the four provided holes offer all of the positions I can think of needing. Throughout this evaluation I used the Quick Lift handle to bring the bits above the table surface for changing with no problems at all. The Quick Lift handle works very well and the spring assist makes getting close to the bit height needed very easy. Then after approximating the bit height I used the crank handle to dial in the exact height required. There really is no “getting used to it” period. Everything worked fine right away.

One thing that surprised me a little was how easy it was to use the crank handle to make height changes while at the same time watching the scale wheel on the Woodpeckers' Side Winder Router Lift surface. If you have arms approximating normal human-length your head winds up right over the scale wheel which makes setting easy and eliminates parallax from the equation.

Conclusions

Video Tour |

The Woodpeckers' Side Winder Router Lift is exceptionally well built using high-end materials and the super accurate CNC machining for which Woodpeckers' has become known. This is a very stable lift that refuses to budge during use which translates to dependable, spot on accuracy.

Raising and lowering the bit/router motor with the Quick Lift handle makes those changes both easy and very quick. The crank handle then allows you to dial in the exact bit height you need with the same speed and accuracy. Whether you are an occasional router table user as most of us are or a true power user the Woodpeckers' Side Winder Router Lift makes your work easier, more accurate and faster overall because of its user-friendly features.

The Woodpeckers' Side Winder Router Lift is Made in America at the Woodpeckers' facility in Ohio yet has a current price of just $359.00! (10-1-2011) The quality and durability of the Woodpeckers' Side Winder Router Lift make it a one-time purchase for nearly all of us. Getting this much quality and ease of use at this price is not a common thing in today’s marketplace. But get used to it as it appears that Woodpeckers' is not going anyplace soon. They are doing well in Ohio.

Visit the Woodpeckers' web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.