|

The Woodpeckers Precision Router Lift comes with everything you need to handle many routing projects with a new level of ease and accuracy.

Click image to enlarge |

Woodpeckers Precision Router Lift

High-end quality, accuracy and value

Text & Photos by Tom Hintz

The ultimate router/lift plate combination marries the power of a big horsepower router with a super accurate lift mechanism that allows above the table bit changing. The patented Precision Router Lift (PRL) from Woodpeckers, Inc. (North Royalton , Ohio) is extremely popular because it maximizes those qualities and more at a surprisingly low price.

Initial Impressions

Everywhere you look, the PRL is heavy-duty and very well made. The machining is top-notch; precisely executing the innovative engineering that has made Woodpeckers products favorites of woodworkers everywhere.

All of the hardware is first rate and the individual pieces made from materials that insure a very long life. Even the all-brass starter pin and crank handle are nicely turned, indicative of the uncommon attention to quality and detail found throughout the PRL.

Solid Plate

|

The high-strength, 3/8"-thick aluminum plate can easily handle the weight of even the Porter Cable powerhouse 7518 router motor.

Click image to enlarge |

The PRL was designed around the industry-leading Porter Cable 7518-2, 3 ¼ Hp motor that weighs in at around 16-lbs. To eliminate the chance of sagging or distortion of the plate under the weight and tremendous torque potential of this motor, Woodpeckers begins with a 9 ¼"-deep by 11 ¾"-wide and 3/8"-thick slab of high-strength, cast aluminum that is blanchard ground to guarantee a very flat platform.

The PRL plate is fitted with spring-loaded brass plungers on one long and one short side that keep the plate snug in the opening as the table goes through temperature-induced expansion and contraction cycles. This is important because it prevents small movements of the plate when the bit starts cutting that can compromise accuracy.

The plate has 8 factory installed leveling screws located around the perimeter that allow the user to make sure it is flush and level with the table surface.

Insert Rings

|

The insert rings install flush with the plate surface every time.

Click image to enlarge |

The PRL comes with three superbly machined insert rings. Rings with a 1" and 2 5/8" inside diameters are supplied along with another that has a stepped, 1 3/16"-diameter hole designed to fit the popular screw-in Porter Cable guide bushings.

The rings are made from high-quality aluminum and precisely machined for a perfect fit. When snugged down with the included wrench the rings seat flush with the plate surface and do not loosen during routing.

A full set of 8 insert rings (Woodpeckers #TLRSET) is available that allows sizing the hole to fit a huge number of bit diameters.

Motor Mounting

|

The mounting boss is massive and guided by two heavy posts to insure perfect alignment.

Click image to enlarge |

A massive 2"-thick slab, cut from a special high-quality aluminum extrusion is machined to clamp the cylindrical PC7518 motor housing with no additional pieces. Insert the motor, tighten the clamping bolts and you are done. Adapter rings are available to fit the Porter Cable 690, 890, Bosch 1617-1618 and Makita 1101 motors.

In addition to securing the motor, the size of the mounting boss controls the torque of modern router motor to insure accurate, wave-free cutting.

Because the PRL mounting boss grasps the motor around the sides only, a huge range of vertical adjustment range is available. This range also allows above-table bit changes with the wrenches that came with the router.

Lift Mechanism

|

|

(Top) The lift mechanism is tough, smooth and wide spread for maximum stability.

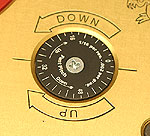

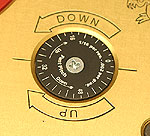

(Bottom) Dual re-positionable scales make tiny changes in bit height simple.

Click images to enlarge |

The PRL lift mechanism is very stable, super accurate and easy operating thanks to a pair of 1/16” or 1/32-pitch threaded, chain-driven lift screws. Using such a fine thread gives the operator a large mechanical advantage over the motor weight and allows very fine adjustment of the bit height.

To keep the lift mechanism stable and true through its entire range of movement a pair of 1.25"-diameter precision-ground guide posts are used. The posts are mounted to the plate 10 ½" apart (the widest in the industry) to keep the router square to the plate surface. When combined with the dual lift screws, the guide posts insure superior accuracy at the bit by preventing even small movements of the motor.

A pair of re-positionable scales in the plate surface indicate one full turn of the crank results in either 1/16” or 1/32" total height change dependent on the lift screw pitch selected. Each of the fine hash marks on the scales represent 0.001" height change, making super-fine changes easy to make with extreme accuracy.

Having two scales can be very handy for routing tasks that involve more than one setting in the process.

Auto-Braking

|

Inserting the crank handle releases the automatic brake for height changes.

Click image to enlarge |

To prevent bit height changes during routing, the PRL has a built-in automatic BrakeLock system. The BrakeLock is released when the height adjustment crank is fully inserted into its socket, depressing a spring-loaded plunger. Remove the crank from the socket and BrakeLock system automatically engages. This system works very well and you can't forget it!

In The Shop

After clamping the PC 7518 motor in place, the PRL was set into the table recess and leveled with the surface. The plate surface was checked to be sure it was flat and that the insert was in fact flush with the surface. Both were dead on.

With a flat-bottomed bit installed in the router, a dial indicator was used to check the accuracy of the bit height scales. Both proved to be right on the money also.

|

Adapter rings are available that make installing smaller motors from Bosch, Porter Cable and Makita a simple task.

Click image to enlarge |

The included height crank and starting pin are both very well made and will last a lifetime, if not longer.

Being able to change bits above the table surface is an obvious plus but the PRL is better in this regard than many lifts. Even with the extended motor case of the PC 7518, the collet can be raised fully above the table surface. The standard Porter Cable wrenches can be used without having to reach down in to the plate opening.

Throughout testing, the PRL lift mechanism was easy to operate and the fine thread made hitting very small changes simple. Bit height was measured before and after routing with no change noted, showing that the BrakeLock feature worked.

The Woodpeckers, Inc. PRL works so well there is very little to comment on. It does exactly what you want every time and when combined with the PC 7518 motor, fears no bit or routing job.

Conclusions

The Woodpeckers PRL is an extremely well made router lift with unique features that are not found on lifts costing far more. The heavily-sized quality materials and super precise machining mean the PRL will be the last router lift you will have to buy unless your standards take a downward turn and replacing it with a lesser unit seems like a good idea.

If quality, function and ease of use are important, the Woodpecker's PRL is the router lift plate for you. With a price of only $289 (2-27-2005) it is a very good value for your hard-earned dollars.

See the PRL on the Woodpecker's, Inc. website.

Do you have a comment about this page? - Email Me!

Back to the Tool Reviews List

|

![]()