This is a Veteran Owned site

|

The Work Sharp® 3000 Sharpener kit shown in this review gets you going right out of the box. Click image to enlarge |

Work Sharp® 3000 Sharpener

An ingenious update of an old sharpening method

Text, photos and video by Tom Hintz

Posted – 3-4-2011

For decades craftsman have sharpened many of their cutting tools by carefully stroking them back and forth on abrasive sheets backed by plate of glass or an exceptionally flat stone. The problem was maintaining the proper angle of the tool during that motion. That often meant one or more jigs purpose designed for holding tools at those angles which increased the cost. Enter the Work Sharp® 3000 Sharpener that uses the same concept but reverses the idea by making the abrasive move predictably while the tool is held motionless. The same highly refined edges are now possible without the frustration but with exceptional accuracy and doing it all more quickly.

The Basics

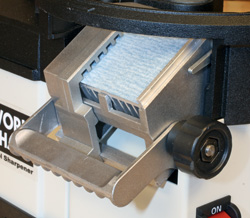

The Work Sharp® 3000 Sharpener is driven by a 1/5-HP motor that uses a torque-enhancing gear drive to produce a final wheel speed of 580 RPM. That wheel is mounted horizontally with tool sharpening access from the top and bottom. There are actually three primary sharpening modes, the Top Side using a Tool Rest, the Chisel and Plane Iron Port mounted under the wheel and the Edge-Vision wheel that is also uses the under-wheel tool rest but with a slotted wheel and abrasive that actually lets you see the edge being sharpened – while it is being sharpened! Try that on the wet grinders!

|

|

From the cast metal top to the tough case and base (left) the Work Sharp® 3000 Sharpener is built surprisingly tough for a tool in this price range. The chisel and plane iron port (right) has a directed air intake and its mass works as a heat sink to minimize tool temperatures during sharpening. Click images to enlarge |

|

The Work Sharp® 3000 Sharpener is ruggedly built from the cast metal top section to a stout sheet metal body and a tool-quality plastic base. The base has ears molded in that allow mounting this tool to a bench or a dedicated workspace. Rubber feet prevent unwanted movement on most clean surfaces.

The Work Sharp® 3000 Sharpener can handle chisel and plane irons up to 2" wide as it comes from the factory. The built-in chisel and plane iron port lets you accurately sharpen them to perfect 20°, 25°, 30° or 35° bevel angles with click-in detents built into the mechanism. These detents also make adding a perfect 5° micro-bevel fast and accurate. This port also features an adjustable guide fence and a skew control to be sure you get a square edge on the tool.

The combination of sharpening modes mean that you can sharpen everything from wood chisels and plane irons to various lathe and carving tools, putty knives and more. Because of the relatively slow 580-RPM wheel speed sharpening does not induce potentially damaging levels of heat. To enhance that heat-fighting theme the Work Sharp® 3000 Sharpener has a directed air flow into the chisel/plane iron port and it uses that same mass as a heat sink to keep the temperature of the tools being sharpened as low as possible.

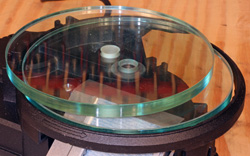

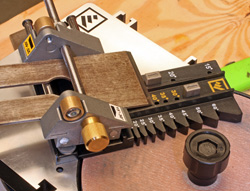

The Work Sharp® 3000 Sharpener uses a fine lapping abrasive sheet mounted on the chisel and plane iron port where it automatically removes backside burrs during the sharpening process. On most other sharpeners burr removal is a totally separate process. Included with the Work Sharp® 3000 Sharpener are 2 tempered glass, 2 sided wheels (150mm diameter) and the unique slotted Edge-Vision wheel that can use solid or slotted adhesive backed abrasives disks that allow you to change grits quickly during the sharpening process. Of course if you use a non-slotted abrasive disk you lose the see-through properties of this backer disk.

|

|

A pair of heavy glass wheels (left) provide solid backing for the stick-on abrasive disks. The slotted wheel (right) uses specially slotted abrasive disks that actually let you watch the edge being sharpened in real time! Click images to enlarge |

|

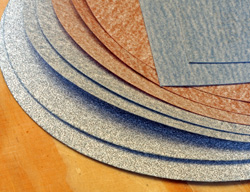

The Work Sharp® 3000 Sharpener comes with 150mm Norton and Micro-Mesh high-end abrasives in aluminum oxide and ceramic grits of P120, P400, P1000 and 3600 that cover most sharpening tasks. The two-sided glass wheels let you have four different abrasives (one per side) at the ready to speed the sharpening process. They also include slotted abrasives in P80, P400 and P1200 grits for use with the very trick Edge-Vision wheel. That works out to 17 abrasive disks to get you started and then some. You even get an abrasive cleaning Crepe Block in the Work Sharp® 3000 Sharpener kit that prolongs the effectiveness of the abrasives.

To demonstrate the manufacturer’s confidence in the Work Sharp® 3000 Sharpener they back it with a full 2-year warranty.

In the Shop

Becoming accustomed to the Work Sharp® 3000 Sharpener involves a nearly nonexistent learning curve. Between the well-done instruction manual and the additional visual support of the included instructional DVD you will be up and running with the Work Sharp® 3000 Sharpener in short order. The Work Sharp® 3000 Sharpener is an easy machine to use but taking the time to review the manual and DVD will get you sharpening perfectly way quicker than hoping for divine guidance.

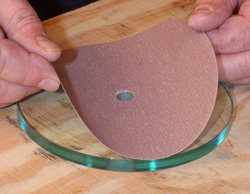

One of the procedures covered on the DVD is a technique for applying the adhesive-backed abrasive disks to the glass and vented disks. If you watch this done on the DVD and then apply the U-shaped technique, getting those round adhesives aligned on the round disks turns out to be very easy.

|

|

The included DVD shows a surprisingly easy way to apply the abrasive disks to the glass (left) and slotted wheels. The tool rest (right) lets you sharpen lots of carving and lathe tools, and others. |

|

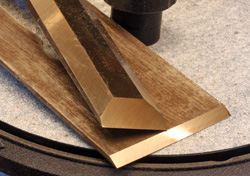

The first thing I did with the Work Sharp® 3000 Sharpener was to freshen the edge of a chisel that I knew had a dead on 25-degree bevel. I set the Work Sharp® 3000 Sharpener chisel and plane iron port to 25-degrees and colored the bevel with a black marker. Using the Edge-Vision wheel I watched as the coloring at the front and back of the chisel bevel began disappearing. Since this chisel had been sharpened on a wheel-type grinder there was a small concave shape in the bevel. After a little more grinding I could see that the color was coming off unevenly. I checked the edge of the chisel and found that it was just a bit out of square. I continued sharpening its bevel until all of the color was gone and re-checked the edge. The Work Sharp® 3000 Sharpener right out of the box had corrected the skewed edge on my chisel which was now nice and square.

Just as surprising was how refined the finish was right off one of the medium abrasive disks. I suspect that the chisel could be used as is. I still had to try the glass wheels so decided to refine this bevel even more on them.

The tool rest and glass disks are also very easy to use and work just as you would expect. Even smaller carving chisels can be sharpened with a bit of practice keeping the bevel flat on the abrasive. Here again coloring the bevel is a good way to confirm that you are grinding the surface you want prepared.

|

|

When I started sharpening the chisel (left) I could watch it take the slight concave shape from the bevel that was caused by the wheel sharpener used before. |

|

The abrasive disks are easy enough to change but using light to moderate pressure lets the disks work without destroying them quickly. However they remain abrasive disks and will wear out eventually but refrain from the heavy-handed techniques and they last longer than I would have expected.

The slotted Edge-Vision wheel was surprising in how clearly I could see the sharpening process as it progressed. It was a little eerie at first watching the black coloring disappear from the bevel only to be replaced with a new ground finish and seeing that all happen in real time. That improved visibility just has to make sharpening go faster and perhaps save some metal. With the old grind – look – grind some more techniques we removed more metal than was necessary because we could not see that the edge as fully ground until we stopped and looked. With the Edge-Vision wheel we can see when the edge is finished or identify problems as they begin to develop which allows you to make the needed adjustments sooner to correct the situation.

The variety of grits that come with the Work Sharp® 3000 Sharpener really does give you a good starting place. Everyone sharpens a little differently and once you get some experience with the Work Sharp® 3000 Sharpener you can buy only the grits you really need and save some tool dollars that way. Your chisels, plane irons and other cutting tools should be more effective longer which also saves money.

Accessories

|

|

The Honing Kit (left) comes with the leather surface adhered to a glass disk, the one-time prep (a type of skin conditioner) and the honing compound. After applying the conditioner (the first time only) and then the honing compound it is ready to shine up edges very nicely. If you like refined cutting edges, this kit is just the thing! Click images to enlarge |

|

Leather Hone - #WSSA0002001

The Leather hone kit gives your Work Sharp® 3000 Sharpener the ability to polish cutting edges to another level of sharp. The kit comes with a 150mm glass wheel with the leather hone adhered to one side so this wheel mounts normally and keeps the leather hone flat and stable.

The kit includes a special conditioner that must be applied to the leather once so that it accepts the chromium oxide honing compound forever afterwards. With the conditioner applied (rubbed in) to the leather we mount the wheel, start it and apply the chromium oxide honing compound.

You can use the tool rest or present the tool by hand to refine the bevel and thereby the cutting edge. The instructions warn against installing the honing wheel upside down to use it from the chisel plane iron port. I’m not sure why that is but I have never seen anyone hone anything upside down so I will follow the directions just in case.

The honing kit makes refining a cutting edge an easy task. Once a tool is sharpened on the Work Sharp® 3000 Sharpener simply honing the edge will often “wake it up” after a little use. I find that my skew chisels start to feel dull after while of turning but just honing the edge brings back that sharp feel and performance.

The Leather Hone kit has a street price of $29.95 (3-2-2011) which makes this kind of refinement cheap!

|

|

The Wide Knife Kit comes with the table, holding jig and a setup jig (left) that make using it very easy. The holding jig (right) can be used on other flat abrasives such as those attached to a pane of glass or flat granite backing. Click images to enlarge |

|

Wide Blade Attachment – #WSSA0002020

The Wide Blade Attachment enables the Work Sharp® 3000 Sharpener to handle blades up to 3”-wide which should cover just about everything in most home or pro woodworking shops. This attachment mounts on the Work Sharp® 3000 Sharpener using the existing tool rest mounts so installation is quick and easy.

The Wide Blade Attachment is made up of three major components. The Honing Guide assembly actually holds the blade at the angle needed. This Honing Guide can also be used on any flat abrasive such as on a pane of glass or granite base. But, it is designed to mate with the flat table that also comes in the kit. The third component is a gauge that measures the existing angle on the blade and uses two pins that are installed in labeled holes to re sharpen or grind that angle into the blade.

The toughest part of installing the Wide Blade Attachment is getting the table level with the disk and that isn’t very difficult. The kit includes the necessary hex wrenches to attach the table to the Work Sharp® 3000 Sharpener mounts and then use the four leveling screws in the table corners to get its surface level to the abrasive disk surface. Follow the well-illustrated instructions inside the package card and you will be grinding precise bevels on your blades quickly. You can also use the Wide Blade Attachment to add a micro-bevel on the edge. We also found that this attachment works well with the Leather Honing kit.

With a street price around $69.95 (3-2-2011) adding the capabilities of the Wide Blade Attachment to the Work Sharp® 3000 Sharpener can make your in-shop life a bunch easier. There really are no consumables in the Wide Blade Attachment kit so this is a one-time investment which makes the per-use cost close to nothing in terms of money but valuable in how it enhances your plane irons and large chisels!

|

|

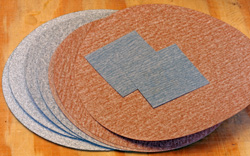

The Coarse Abrasives Kit (left) gives the Work Sharp® 3000 Sharpener more bite for reshaping or other major grinding jobs. The disks (right) are just like the ones that come with the sharpener with pressure sensitive adhesive backs. Click images to enlarge |

|

Coarse Abrasives Kit - #WSSA0002005

If you do a lot of heavy grinding as when changing the overall shape of a chisel or blade using more aggressive abrasives makes the job go faster and easier. The Coarse Abrasives Kit comes with pressure sensitive disks just like the originals that came with your Work Sharp® 3000 Sharpener but in coarse grits.

Included are 2 - P80 disks, 2 - P120, 3 - P220 and 2 - P400 grit disks. Also included are two square abrasive pieces for the under-disk chisel and plane iron port. If this type of grinding is common in your shop you might consider getting a couple more of the glass disks and leave them set up with the coarse grits you use most.

However you do it, the Coarse Abrasives Kit gives provides fast material removal rates for major reshaping jobs. With a street price of just $14.99 (3-3-2011) you can extend the capabilities of your Work Sharp® 3000 Sharpener at a very reasonable cost.

|

|

The Belt sharpening Kit (left) comes with everything you need for sharpening many knife and scissor styles. The kit comes with 3 abrasive types and there are more available as accessories. The angle adjuster is easy to use and lets you choose the best angle for your job. Click images to enlarge |

|

Belt Sharpening System - #WSSA0002780

Designed specifically for use on the Work Sharp® 3000 Sharpener the Belt Sharpening System makes sharpening blade type tools such as kitchen, pocket and marking knives as well as common scissors a simple but very effective chore.

The Belt Sharpening System attaches directly to the Work Sharp® 3000 Sharpener in an existing mount so there are no modifications of your machine required. Aside from the simple belt tracking dial the only adjustment is setting the bevel angle between 10 and 35-degrees for virtually any knife and 55 to 80-degrees for scissors.

The Belt Sharpening System large drive pulley replaces the Work Sharp® 3000 Sharpener locking knob that secures the glass or slotted wheels. In fact you need to leave a glass or slotted wheel in place beneath the Belt Sharpening System drive pulley.

Video Tour |

The Work Sharp® 3000 Sharpener Belt Sharpening System comes with three belts. One P120, one P220 and one 6000 grit 1” by 18” belt are included. There are also ½” by 18” belts in X200, X65, 3600 (Micro-Mesh) and 12000 (Micro-Mesh) grits as well as a 1” by 18” leather stropping belt available as accessories.

The Belt Sharpening System also has the capability to sharpen many carving and turning tools and probably more depending on what you do in your shop. With a street price of just $59.95 (3-3-2011) you can add a whole new level of use for your Work Sharp® 3000 Sharpener.

Click Here to check pricing and availability at Woodcraft.

Click Here to visit the Work Sharp web site.

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.